Sign Up Today

Find Your Manufacturing Solution in The Shooting Star Technical Brief

Use the content filter to narrow the newsletter issues by material focus. Click on any thumbnail to read that issue.

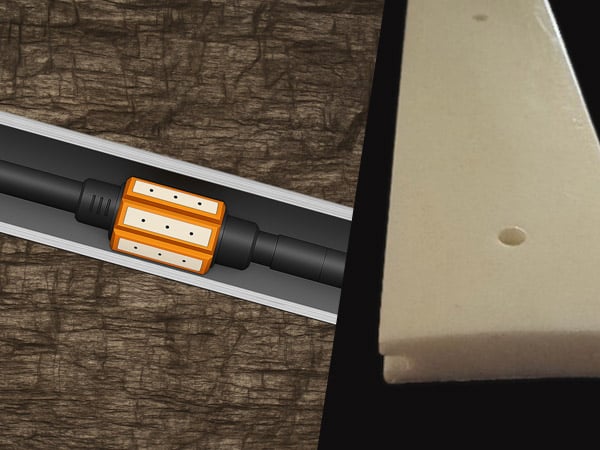

CJ and Ultracomp® Bearings for High-Load Wire Rope Catenary Systems

Explore this Application

Ultracomp® UC300AX Bearing Pads for High-Load Autoclave Supports

Explore this Application

Preventing Flashover: Conductive Composite Tools for Military Coatings

Explore this Application

Lightweight, Lubrication-Free Rollers for Harsh Drilling Environments

Explore this Application

Ultracomp® Conveyor Wheels Keep Automotive Lines Moving

Explore this Application

Ultracomp® Bearings Keep Navy Munitions Moving

Explore this Application

Self-Lubricating Bearings Solve Critical Vacuum Deposition Challenge

Explore this Application

TriStar Engineering Advances Non-Rotating Protector Performance

Explore this Application

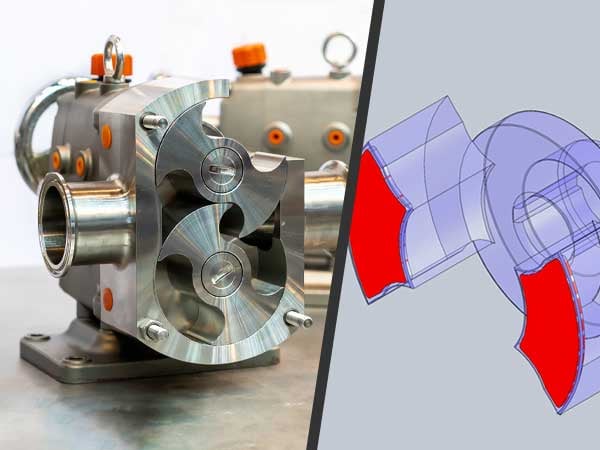

Innovative Compressor Components for Evolving Demands

Explore this Application

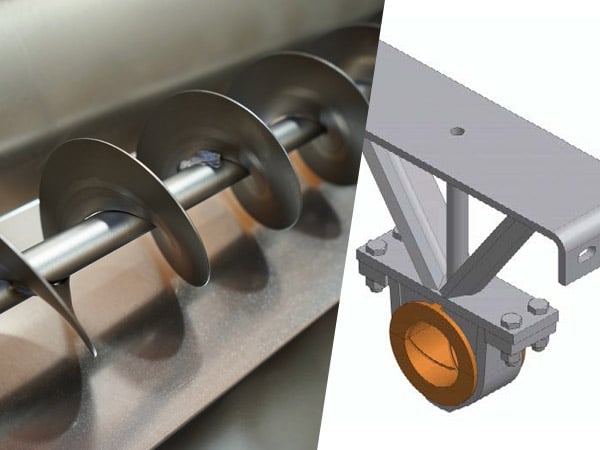

Ultracomp® Composites Improve Classic Archimedes Screw

Explore this Application

Rulon® J: Reducing Micro Vibrations in Contact Lens Production

Explore this Application

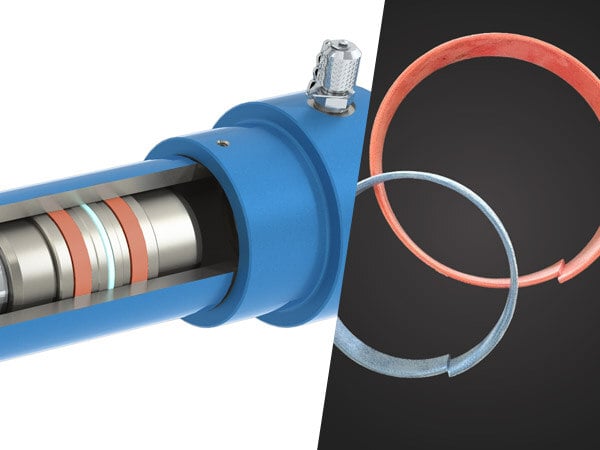

Wear Ring Solutions for High-Performance Hydraulic Cylinders

Explore this Application

Rulon® 123 “Shoes” Vanquish Elevator Door Rattles

Explore this Application

Ultracomp® Composites Lift Up First Responders in Fire Truck Application

Explore this Application

A Screw Nut Engineered to Fail for Advanced Cancer Treatment

Explore this Application

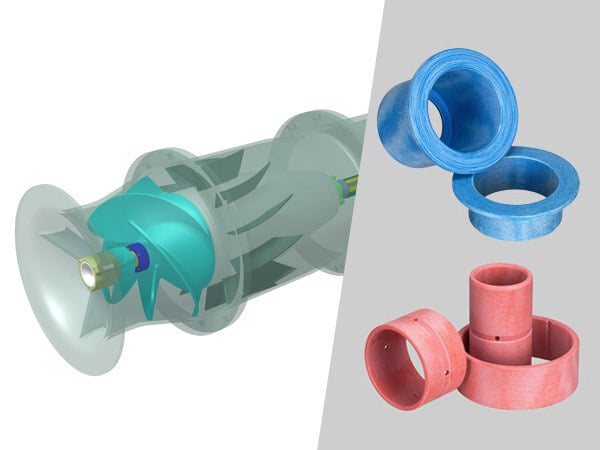

Bearing Material Solutions for Downhole Vertical Pumps

Explore this Application

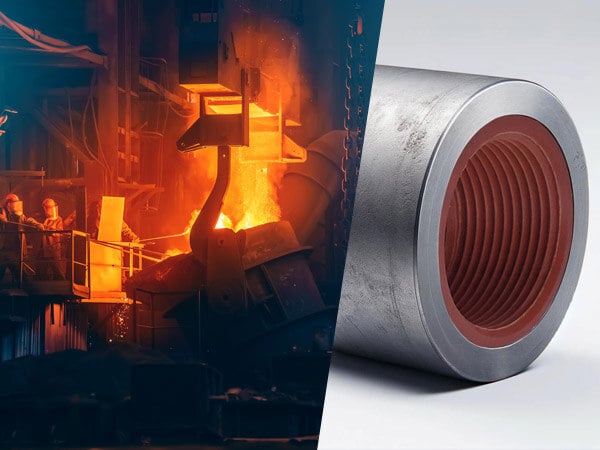

Rulon® AR: Providing Corrosion Resistance in Steel Mill Cooling Systems

Explore this Application

How TriStar Helped Extend the Life of the C-5 Galaxy

Explore this Application

Ultracomp® Composites On-Track for Critical Railway Components

Explore this Application

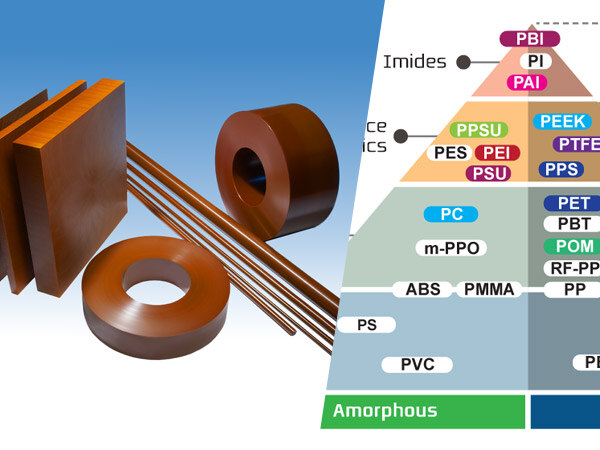

Imides: The Ultimate High-Performance Plastics

Explore this Application

Rulon® Materials Enhance Animatronics

Explore this Application

Engineering a Unique Seal to Contain Micro-Meteor Damage on the International Space Station

Explore this Application

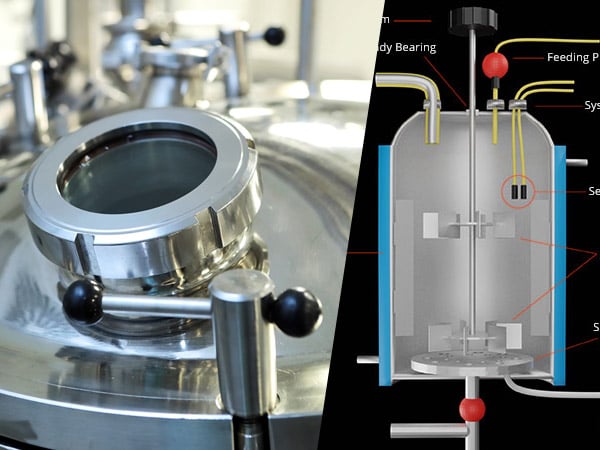

Plant-Based Food Trends Require Careful Mixer Bearing Selection

Explore this Application

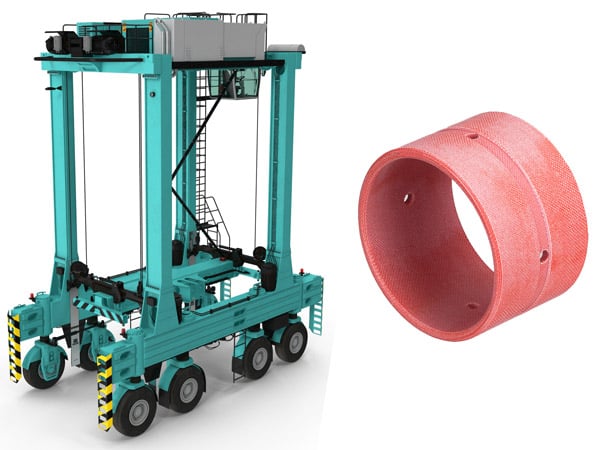

Ultracomp® Composites Enhance Durability of Steel Mill Straddle Carriers

Explore this Application

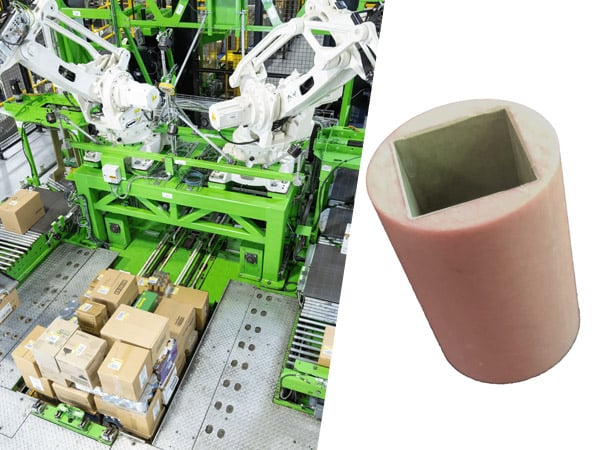

Custom FCJ Bearings Power Robotic Automation System

Explore this Application

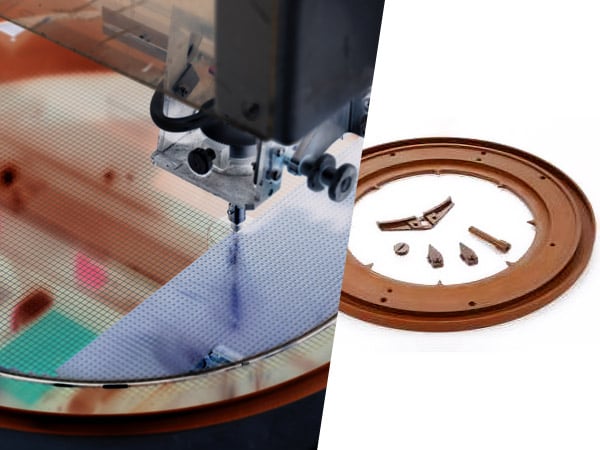

FDA Compliant Rulon® 641 Silences ‘Squealing’ in Sanitary Fabric Machine

Explore this Application

TriStar EMD Uses Spectrography to Solve a Metal Mystery

Explore this Application

Engineering a Better Autoinjector Seal for Precise Serum Delivery

Explore this Application

Rulon® 488 A Game-Changer For High-Temp Applications

Explore this Application

The Iconic B-52 Jets Into the Future With Tristar

Explore this Application

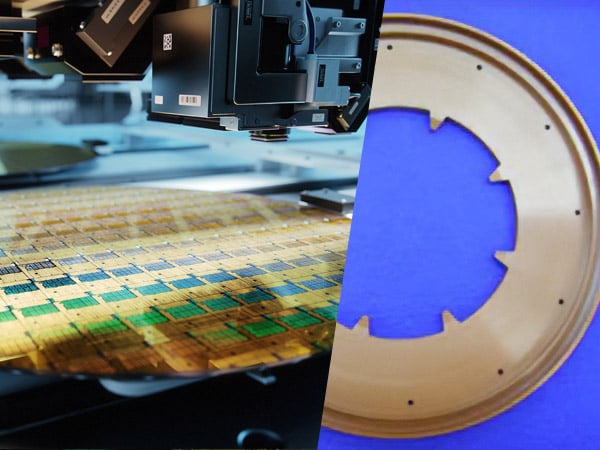

Surveying the High-Performance Plastics Used in Semiconductor Manufacturing

Explore this Application

Ultracomp® Self-Lubricating Composite Bearings for Ferry Dock Systems

Explore this Application

PFAS – The Quest for Alternatives to Harmful “Forever Chemicals”

Explore this Application

Rulon® 1439 Solves Turbine Flow Meter Bearing Issue

Explore this Application

High-Performance Bearings and Seals Advance Oceanic Research

Explore this Application

Meldin® 7001 Seals the Deal in Paint Sprayer Application

Explore this Application

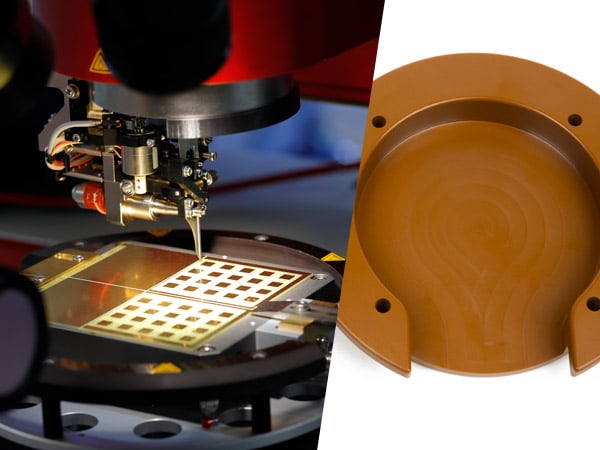

Meldin® 7001 Polyimide for Semiconductor Wafer Production

Explore this Application

Rulon® 945 Outperforms in Dry Gas Piston Compressors

Explore this Application

Ultracomp® Marine-Grade Bearings Excel at Power Hoisting & Hauling at Sea

Explore this Application

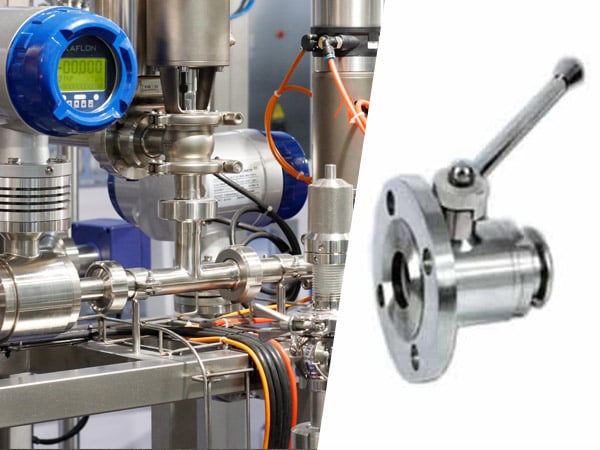

FDA-Cleared Rulon® 641 Improves Process Analytics Valves

Explore this Application

TriSteel™ HMT – A Hardened Steel Bushing for High Impact Applications

Explore this Application

Meldin® 7001 Polyimide for Semiconductor Manufacturing

Explore this Application

Meldin® Polyimide Application Showcase

Explore this Application

Omniseal/TriStar Announce Exclusive Distribution Agreement for Meldin®

Explore this Application

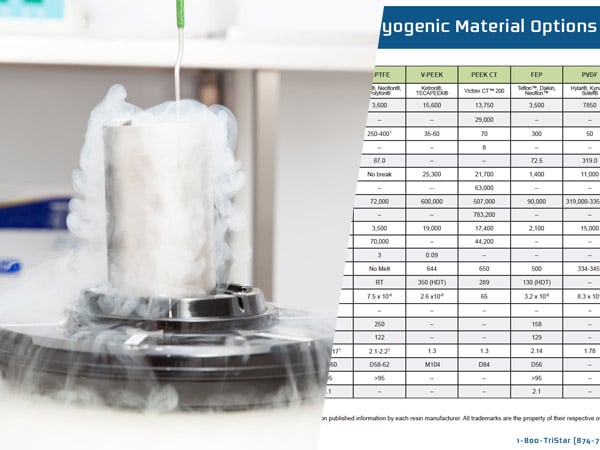

Supply Chain Issues and Sourcing Cryogenic Polymers

Explore this Application

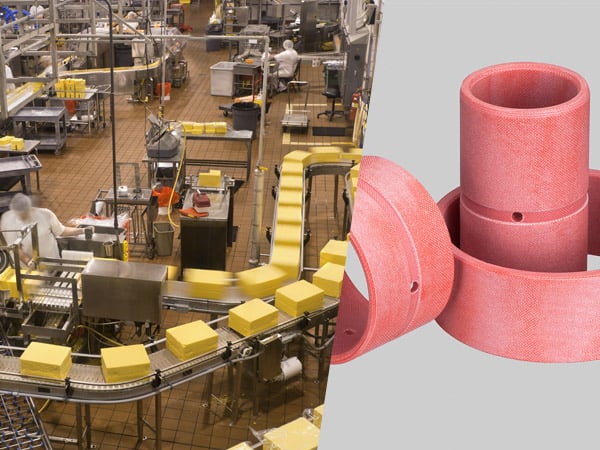

Rulon® 1439 Bearings Keep Hummus on the Table

Explore this Application

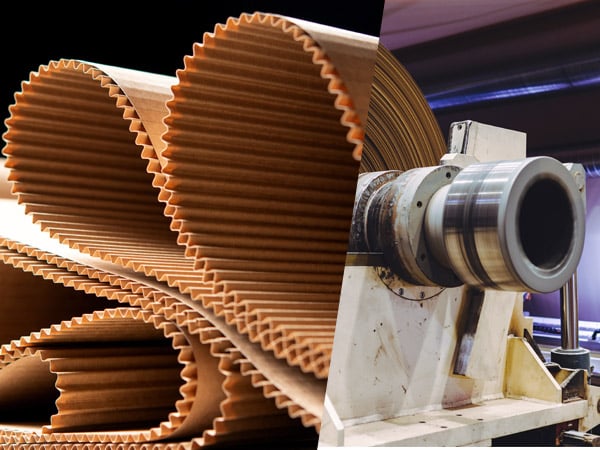

Self-Lubricating Bearings Boost Corrugated Cardboard Production

Explore this Application

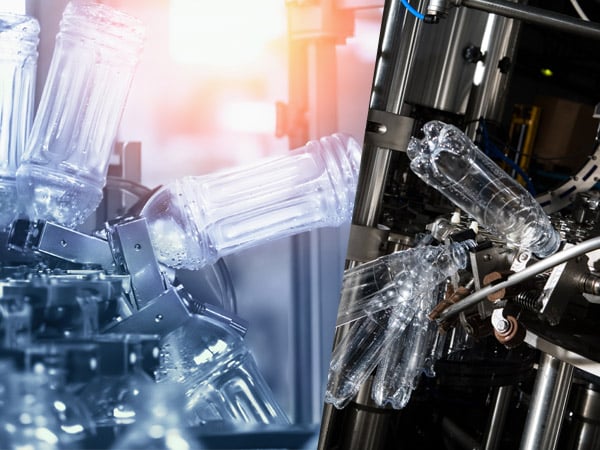

Creative Approach Solves Corrosion Issue on Bottle Washing Equipment

Explore this Application

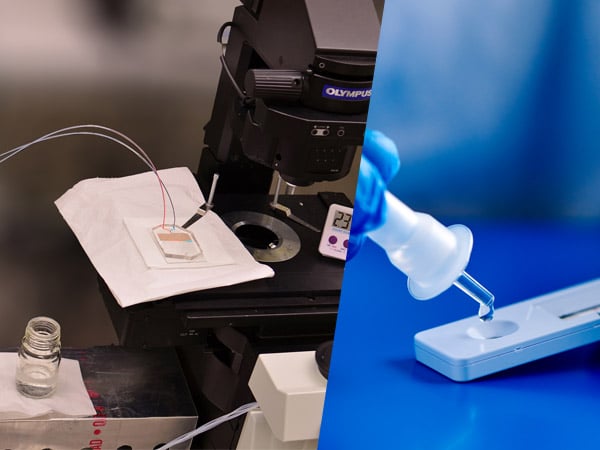

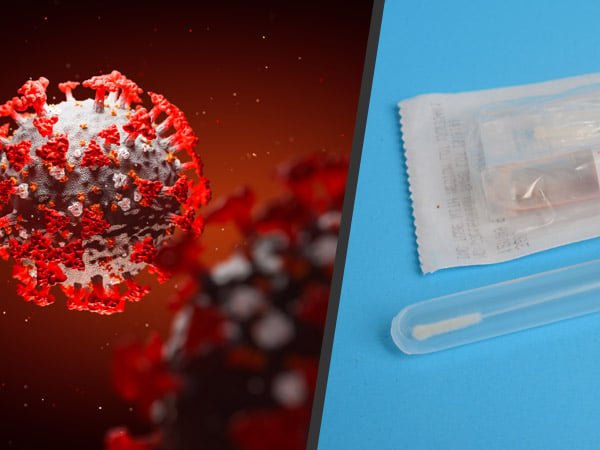

Improving Droplet Dispensation Systems for POC Device Manufacturing

Explore this Application

CJ Bearings for Reliable Long-Term Service in Marine Thrusters

Explore this Application

Education Creates Strong Partnerships

Explore this Application

Selecting Polymers for Diagnostic Microfluidics

Explore this Application

Rulon® J has the Edge in Blade Manufacturing

Explore this Application

A Hybrid Bearing Approach Proves Itself in Heavy Mining Equipment

Explore this Application

Rulon® Bearings Excel as Drop-in Replacements for Bioreactor Steady Bearings

Explore this Application

HyComp H310™ Solution Quadruples Lifespan of Forging Manipulator

Explore this Application

TriSteel Bearings Keep Triangular Drive Systems on Track

Explore this Application

FCJ Bearings a Ray of Sunshine in Solar Panel Arrays

Explore this Application

Rulon® 1439 Bearings Increase Potato Chip Production Rates

Explore this Application

Cold Plasma Treatment Helps Implant Dentistry Create Beautiful Smiles

Explore this Application

Clever Material Selection Extends Operating Life of Bottling Equipment

Explore this Application

Riding the Waves with Self-Lubricating CJ Bearings

Explore this Application

Advanced Materials Improve Uptime & Outcomes in Cheese Manufacturing

Explore this Application

Self-Lubricating Bearings Boost Performance in Screw Conveyors

Explore this Application

Composite Bearings for Onboard Seafood Processing and Packaging

Explore this Application

Ultracomp® Bearings Ensure Rapid Deployment of Navy Transport

Explore this Application

CJ Bearings Ensure Smooth Sailing for Sailboat Windvanes

Explore this Application

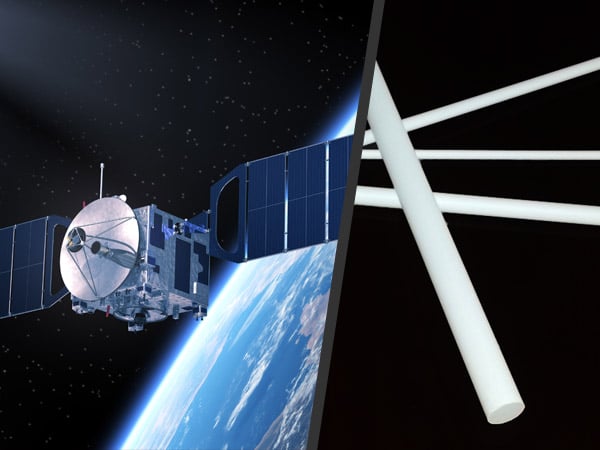

Fluoroloy® H Brings Superior Thermal Conductivity to Satellite Application

Explore this Application

Surface Modification Techniques for Rapid COVID-19 Testing

Explore this Application

TriSteel™ PT Metal-Backed Bearings Raise Hoist Effectiveness

Explore this Application

Asymmetric PES Membranes Enable On-Device Blood Testing

Explore this Application

Special PEEK Rotor Insert Eliminates Failure in Chemical Pump

Explore this Application

Roasting a Better Cup of Comfort with Rulon® 641

Explore this Application

TriSteel & Ultracomp Bearings Clean up in Renewable Energy

Explore this Application

Ultraflon CFX30 Performs in Extreme Oil & Gas Seal Application

Explore this Application

Don't Settle for Bronze - CJ Bearings are Ideal Drop-In Replacements

Explore this Application

Rulon® 641 in the Mix with Reduced Wear & Noise

Explore this Application

Rulon® J Makes it Possible to Strap in and Feel the "G's"

Explore this Application

Rulon® Mission-Critical in Chernobyl New Safe Confinement System

Explore this Application

Hyper-Hydrophobic Membranes Elevate Liquid Chromatography

Explore this Application

Rulon® Brings Top Sound/Vibration Dampening to High End Audio

Explore this Application

Rulon® Materials are Critical for Accurate Lab Fluid Dispensing

Explore this Application

CJ Bearings Kick Grease Contamination to the Curb

Explore this Application