Custom Fabrication

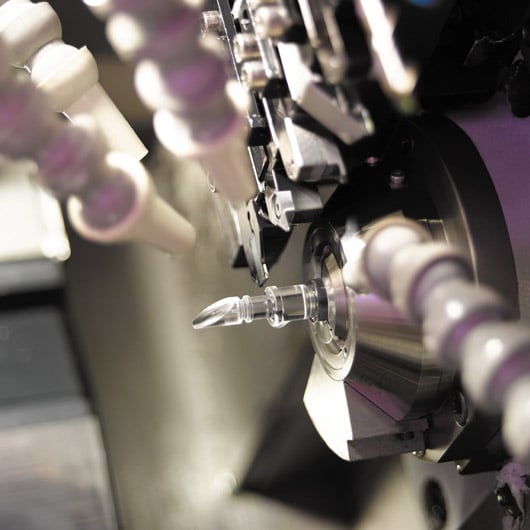

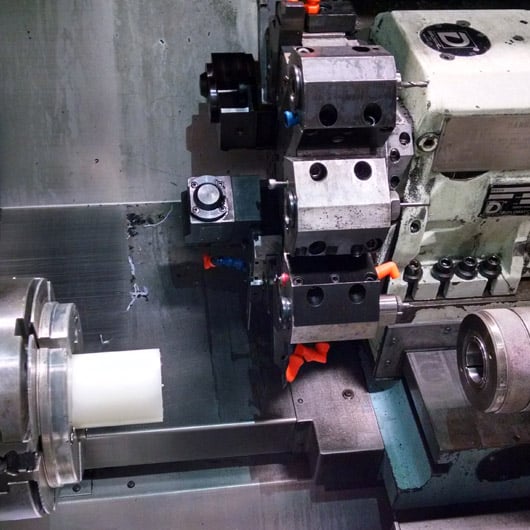

From Prototype to Production - CNC Milling, CNC Swiss Screw, CNC Turning

In our state-of-the-art fabrication facility hosting the latest in CNC machinery, we’ve got the right machine tool to customize plastic fabrication for any manufacturing project.

From small-diameter screw machines to large-diameter turning centers and even large-capacity milling centers, our plastic fabrication capabilities offer an array of affordable and flexible options that are customizable for your unique project.

All our machinists and quality control technicians are highly trained in the art of machining plastics. Our team excels in custom plastic fabrication from prototype to production.

Do you have a question for our bearing experts?

Custom Components

Watch our quick video overview of TriStar's custom fabrication capabilities.