Meldin®

A Family of High-Performance Solutions

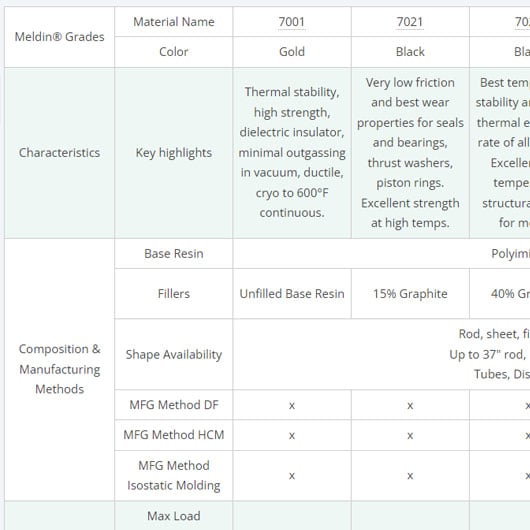

Meldin® Polyimides

High-Performance Thermoset Materials

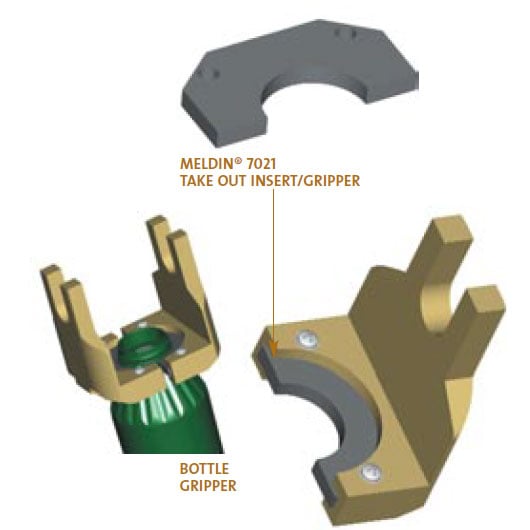

Meldin® polyimide materials are engineered for high-demand applications.

These materials exhibit high dimensional stability and can be used in specialized applications where high thermal resistance and good mechanical properties at high temperatures are required.

They retain their critical properties at continuous operating temperatures from cryogenic through 600°F and can be used intermittently up to +900°F.

These lightweight materials can withstand harsh chemicals, high pressure, and extreme speeds, friction and wear.

These materials are suitable for metal and ceramic replacement and ideal for applications in many industries including industrial, semiconductor, aerospace, and life science. Read our deep dive to learn more about Meldin®.

Meldin® 7022

40% Graphite Filler

Meldin® 7211

10% PTFE, 15% Graphite Filler

Meldin® 6000 Series

Hybrid Aromatic Polyimide

Meldin® 2000 Series

Polyimide Resin Base

Meldin® HT Thermoplastics

Diverse Array of Engineered Meldin® Thermoplastics

Meldin® HT (High Temperature) thermoplastic materials include multiple moldable materials designed for applications where high thermal resistance and good mechanical properties are required.

Additional benefits include low weight and corrosion and chemical resistance, making them extremely attractive and versatile when replacing metals.

Meldin® HT Thermoplastic materials are classified as high performance polymers and are ideal for specialized applications in demanding industries such as aviation, space, life sciences, and semi-conductors.