White Papers

Explore Guides Covering Bearings, Plastic Materials, and Key Industries

Use the content filter to narrow the white papers down by topic focus.

Click on any thumbnail to learn more.

Engineering Services

How TriStar Helps Customers Source Components That Deliver Exceptional ROI

Military Components

How High-Performance Polymers Solve Engineering Challenges

Aerospace Components

Why High-Performance Polymers are Critical for Aerospace Applications

Semiconductor Manufacturing

How Meldin® Can Boost ROI for Plasma Deposition Components

Meldin® Materials

Why Meldin® Offers Extraordinary Value for Challenging High-Temperature Applications and Beyond

Enhanced Materials Division

Solving Tough Engineering Problems with Enhanced Materials and Specialized Engineering Services

Pulp and Paper Equipment

How Careful Material Selection Can Solve Key Engineering Challenges for Pulp & Paper OEM’s

Plastic Bearing Design

A Guide to Form, Function and Selection

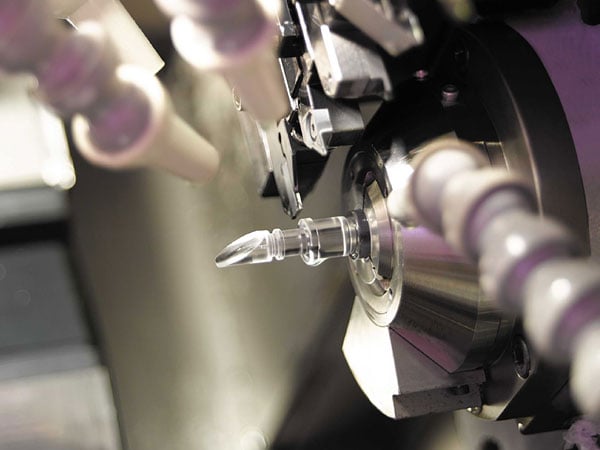

Machining Plastics

The Essential Guide to Materials, Tools & Techniques

Why do Metal Bearings Fail?

A Guide to Primary Causes and Tips for Prevention

Oil and Gas Equipment

How Advanced Polymer Components Are Solving Problems Across the Oil and Gas Industry

Railcar Equipment

How Advanced Self-Lubricating Bearing Materials are Helping Rail Cars and Related Equipment Operate More Safely and Efficiently

Food and Beverage Industry

Challenges for Processing, Packaging, and Beyond

Critical Bearing Metrics

How to Choose the Best Bearing for Your Application

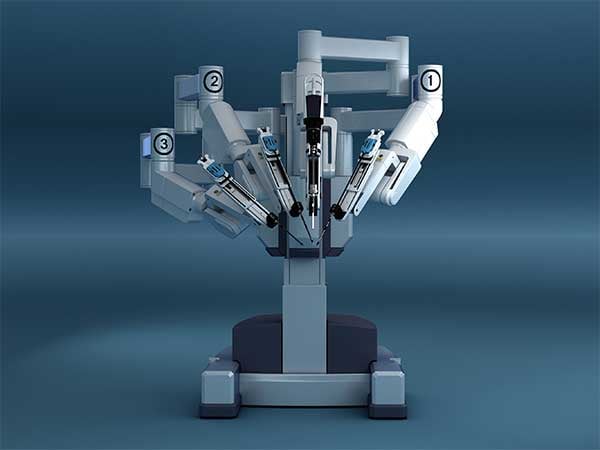

Robotics and Manufacturing

A Guide to Bearing Selection for Increased Production

Composite Bearings for Manufacturing

Ready to Improve Your Output? Grab this Guide to learn how!

Rulon® Bearings

How to Recognize Genuine and Avoid Counterfeit

Surface Modification

Improve Adhesion, Micro-Clean, and Hydrophobic or Hydrophillic Characteristics

Food Processing Equipment

How Advanced Polymer Components Can Solve Key Production Challenges

Food & Beverage Packaging

The Value of Self-Lubricating Polymer Components

Agricultural Machinery Design

How new bearing innovations are propelling the industry with increased efficiency, productivity, and greater value

Rulon® Engineered Materials

Quality Assurance Begins with Precision Processing