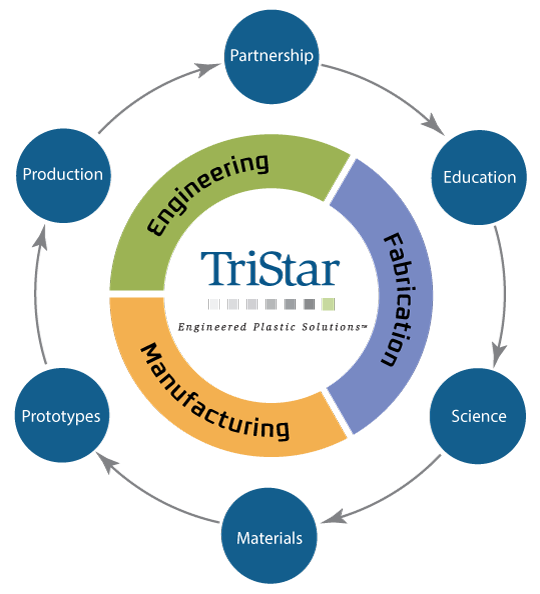

The TriStar Advantage

At TriStar, the Advantage is yours.

Engineering

Our technical staff is dedicated to helping you choose the right material and component geometry for your application. You will benefit from our ongoing research of the latest products, as well as our design experience managing thousands of applications.

From our in-house engineers assisting you with your application to a member of our technical team visiting your facility and conducting seminars to educate your staff on how and when to use the right material, our goal is clear: to become your in-house plastics engineering department.

Key Services: Material ID/research, CAD/CAM services, component geometry, calculating PV, on-site technical seminars

Fabrication

TriStar excels in custom plastic fabrication from prototype to production. Our state-of-the-art fabrication facility features the latest in CNC machines – from small diameter Swiss screw machines to large diameter CNC turning centers and large capacity CNC milling centers. All our machinists and quality control technicians are highly trained in the art of machining plastics, making sure your parts are right the first time, every time.

Key Services: CNC Turning, fabrication, CNC milling

Manufacturing

Manufacturing composite bearings and bearing materials allows us to offer custom blends and unique sizes that others simply can’t. Producing our own materials in-house enables us to implement your designs on time, on budget, giving you a strategic advantage over your competitors. At TriStar, there’s no such thing as a standard. Your requirement is our standard.

Key Services: Prototyping (quick turnaround), precision workmanship, rigid QC (ISO 9001:2015), fabrication, manufacturing of CJ, Ultracomp and TriSteel bearings systems