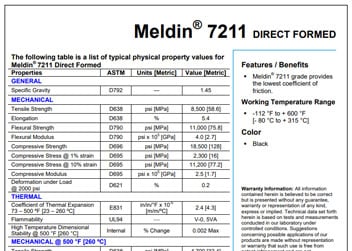

Meldin® 7211 | 10% PTFE & 15% Graphite Filler

Meldin® 7211 has 10% PTFE and 15% graphite filler, which provides the lowest coefficient of friction of the 7000 series polyimides.

This material is an excellent high-temperature, high PV bearing material in dry service.

Above 300°F we recommend using Meldin® 7021 instead, which has a very similar coefficient of friction to 7211 with a lower wear factor at those temperatures.

Need More Info about Meldin® 7211

|

Description |

Thermoset Polyimide with 10% PTFE and 15% Graphite Fillers |

|

Color |

Black |

|

Benefits |

Lowest coefficient of firction of any Meldin® 7000 series grade |

| Working Temperature Range | -112°F to +600°F [-80°C to +315°C] |

| Manufacturing Methods | Isostatic molded Direct formed Compression molded |

| Shape Availability | Rod (up to 37") Sheet (12"x12") Finished parts Tubes, discs, blocks |

|

Agency Approvals |

Meets ASTM D6456-99 Type 2, Class 3 Meets AMS3644 Class 4 Meets Mil-R-46198 Type 2, Class 3 (superceeded) Meets Honeywell MCS5016 Type 2, Class 3 Meets Rolls Royce MSRR9205 |

| Replaces | Vespel® SP-211 |

Vespel is a Registered Trademark of DuPont Polymers, Inc.