Selecting Polymers for Diagnostic Microfluidics

The engineers in our Enhanced Materials Division (EMD) have recently seen an increase in the number of requests to help develop microfluidics for the invitro diagnostics industry. There are many technical considerations in designing these devices, and polymer choice is one of the critical decisions that should be considered carefully. In this issue we talk about polypropylene – a common polymer used in a variety of medical and diagnostic applications. The most important is – which one to choose?

How a Polymer is Produced Can Greatly Affect its Physical Properties and Performance

Most polypropylene will be polymerized with a metallocene or a Ziegler-Natta catalyst. These compounds – as well as others like clarifiers, nucleation, colorant and radiation stabilizers – can cause differences in the polymerization structure thereby affecting physical properties of the polymer.

Metallocene catalysts like half titanocenes/MAO, zirconocenes, and other single site catalysts can control various important parameters, such as co-monomer distribution, molecular weight, molecular weight distribution, molecular architecture, stereo-specificity, degree of linearity, and branching of the polymer.

A Bit More on Ziegler-Natta Catalysts – Two Classes with Different Strengths

When producing polypropylene, Ziegler-Natta catalysts are most often specified. On the basis of solubility, the Ziegler-Natta catalyst has been categorized into two major classes:

- Heterogeneous Catalysts – These are industry-dominating catalysts that are based on titanium (and sometimes vanadium-based) compounds and used for polymerization reactions, usually in combination with organo-aluminum compounds like tri-ethylaluminium (TEA=Al(C2H5)3) as co-catalysts.

- Homogeneous Catalysts – These are the second broad class of catalysts and are based on complexes of Titanium (Ti), Zirconium (Zr), or Hafnium (Hf). They are generally used in combination with a range of different organo-aluminum co-catalysts known as metallocene/methylaluminoxane (MAO). Traditionally, they include metallocenes but also feature multi-dentate oxygen- and nitrogen-based ligands.

This is important to know because of potential interference with the assay or contamination of the sample. Ziegler-Natta catalyzed polypropylene can contain a broader molecular weight range of polymer chains. The low molecular weight oligomers ‘bloom’ to the surface and can interfere with the contents of the molded device or subsequent processes.

The Structure of The Polypropylene can Vary by Production Method – Thus Affecting its Properties

In addition, physical properties of the bulk polymer resin catalyst and polymer structure can be observed:

|

Type of Polypropylene |

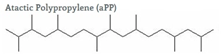

Atactic Polymer where the substituents in a carbon chain are arranged in a random manner |

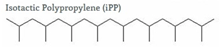

Isotactic Polymer which has the substituents on the same side of the carbon chain |

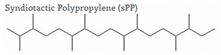

Syndiotactic Polymer which has the substituents in an alternating pattern along the backbone |

|

Structure |

|

|

|

|

Glass Trans. Temp. (Tg) |

-10°C |

-8°C |

0°C |

|

Melting Temp. (Tm) |

NA |

160°C |

184°C |

The table above does not indicate a Tm (melting temp) for atactic polypropylene since a Tm is only a property of semicrystalline and crystalline materials. Following, this would mean that Isotactic and Syndiotactic polypropylene do have crystalline morphology. This crystalline morphology is important to know because the injection molder needs to know at what temperature to hold the tool for the crystallites to form.

When the molder is processing, this crystallization temperature dictates the required mold temperature range. If mold temperatures are set below this range then the chances of the formation of crystallites is reduced, thus affecting the physical properties.

Tristar EMD is Standing by to Assist with Advanced Material Selection (and Enhancement)

So, clearly there are many technical factors to consider when developing or choosing polymers for invitro diagnostic applications. Our EMD engineers are committed to working with your team to assist you in bringing these products to market.

We can help in all aspects of design and development of your medical diagnostic, aerospace, or industrial product and we have direct connections to resin manufacturers, adhesive developers, machinists, laser welding/cutting providers, and more. If you have an application you’d like us to take a look at, please reach out to our experts to get the conversation started.