Creative Engineering Approach Solves Corrosion Issue on Bottle Washing Equipment

A large water bottling company contacted TriStar’s engineers concerning some problems with their washing equipment. This company bottles true spring water that comes from glacial sources and, accordingly, the water flows through natural filtration directly from the source to the outlet. As this happens an interesting collection of minerals accumulates, which led to rapid corrosion of the stainless-steel machine components.

A Little More About the Bottle Washing Process

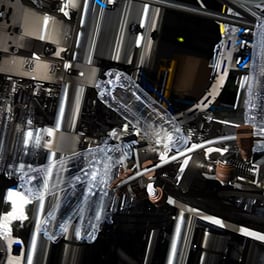

After the customer molds the PET preform and then blow molds the finished bottle, the bottles must go through a high-speed water rinse system. The bottles are loaded upside down on the machine (20,000 per hour) and the water is shot into the bottle while the turret revolves at very high speeds. Once a full revolution is completed, the bottles are released to move on to the filling stations.

The issues TriStar was asked to help resolve occurred due to the high mineral content in the drinking water, which was leading to premature corrosion of the stainless components. Specifically, the spray valve cams, the cam ring and the valve stem bearings.

The challenge in this case was to find materials that, in addition to the corrosion resistance, would also be FDA and NSF compliant, tolerate clean-down solutions, handle high dynamic motions, and be compatible with stainless steel surfaces.

Three Unique Problems – Three Unique Solutions

- Spray Valve Cams – We replaced the acetal roller/sealed ball bearing combination with a Torlon 4301 roller/bearing combination. The design required a little modification to the method of installation but made for a much more reliable (albeit expensive) solution.

- Cam Ring – This is a large diameter (7 ft) round bar ring made of stainless steel and we developed a custom extruded snap-over C ring to cover the area where the valve cams run 24/7. The material we chose was UHMW since it is inexpensive and can be easily replaced as needed. We came up with a clever attachment system where each joint around the circle would be smooth but easily worked with during maintenance.

- Valve Stem Guide Bushings – These internal stem bearings see rapid open and close cycles as they produce the spray into the bottle, hold, and shut down thousands of cycles per hour. TriStar chose Rulon 641 for this very small (1/4” shaft size) bushing because of the material’s low friction, wear resistance and clean down compatibility.

These changes, in combination, successfully mitigated the corrosion issue, significantly reducing maintenance windows and cost.

The Tristar Advantage – All the Resources You Need, When You Need Them

This is just one example of TriStar’s consultative approach to engineering. We frequently work with customers to combine their unquestionable expertise in their own businesses with our decades of experience in bearing design and material selection to come up with creative solutions to tricky problems. If you have an engineering problem that could benefit from this approach, we encourage you to reach out to our experts.