Bearings and similar components play a critical role in overall equipment performance, reliability, and service life. Yet in many designs, material selection is treated as a secondary decision; often driven by habit rather than engineering analysis.

At TriStar Plastics, our application engineers regularly work with OEMs and maintenance teams across applications ranging from advanced military to food processing. In these environments, we consistently see that thoughtful material selection, paired with early engineering input, can dramatically reduce downtime, maintenance costs, and unexpected failures.

In this article, we explain why bearing material selection is an engineering priority, how advanced polymers and composites outperform traditional metals in many applications, and how TriStar supports customers through material selection and component design; not just part supply.

(For a general overview of bearings please see our Bearings 101 resource here.)

Bearing Materials Selection: An Engineering Priority

Generalizations about bearing materials can be costly. Many organizations default to bronze or metal-backed bearings simply because they have “always worked.” But new equipment designs and modern operating environments introduce new stresses that legacy materials were never optimized to handle.

Examples include:

- Dusty or abrasive environments where grease attracts particulates

- Washdown or chemical exposure in food, beverage, and pharmaceutical equipment

- High load, oscillating motion, where misalignment and vibration accelerate wear

- Cleanroom or vacuum environments, where lubricants are prohibited

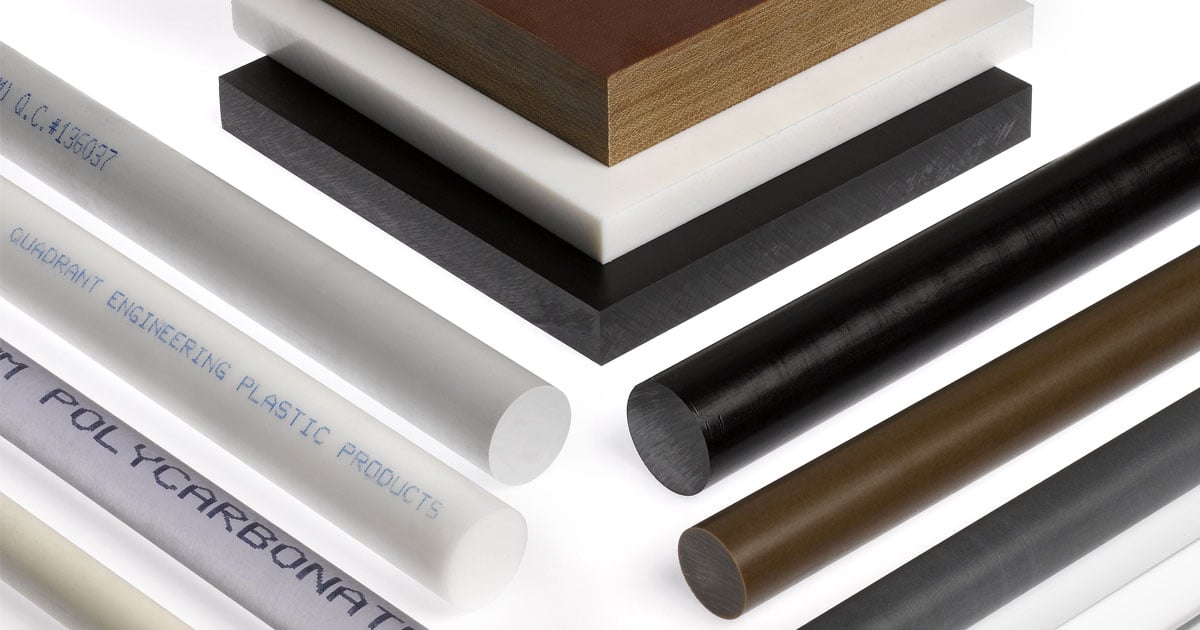

Material assumptions can also limit innovation. A common misconception is that plastic bearings are only suitable for low loads or low temperatures. In reality, engineered polymers and composite bearings—such as Rulon®, Ultracomp®, CJ®, and TriSteel®—are routinely designed for high loads, wide temperature ranges, and aggressive environments as seen in our materials database.

With accurate material data and application-specific engineering, polymers often outperform metals while eliminating lubrication altogether.

Priorities for Effective Bearing Selection

1. Material Properties Matter; Even Within the Same Category

Not all polymers behave the same. Load capacity, PV limits, wear rates, chemical resistance, and thermal stability vary significantly between formulations.

- Rulon® PTFE-based materials excel in low-friction, clean, or regulated environments

- Ultracomp® filament-wound composites thrive under high loads, vibration, and contamination

- TriSteel® bearings combine metal structural strength with self-lubricating polymer liners

In many cases, materials can be customized, or layered, to balance competing requirements. This is why material selection should be data-driven, not category-based.

2. Application-Specific Engineering Beats “Best Material” Thinking

There is no universal “best” bearing material. The right solution depends on:

- Load type (static vs. dynamic)

- Motion (rotary, oscillating, linear)

- Speed and PV limits

- Environmental exposure (chemicals, dust, moisture)

- Access for maintenance or lubrication

TriStar engineers work directly with customer design teams to evaluate these variables early in the design cycle. In complex assemblies, different bearings within the same machine often require different materials to achieve optimal performance.

3. Total Cost of Ownership (TCO) Outweighs Initial Part Cost

Material selection is not just about avoiding catastrophic failure. The true cost of a bearing includes:

- Maintenance labor

- Lubrication systems and grease consumption

- Downtime from seizure or contamination

- Cleaning and regulatory compliance>

- Damage to mating components>

In one customer application, a simple bearing material change eliminated grease-related downtime and saved over $300,000 annually through reduced maintenance and lost production.

Expert Note from TriStar: The most successful bearing solutions start with collaboration. Our engineers don’t just recommend materials; we evaluate load, motion, environment, shaft finish, and housing design together. That systems-level approach is what allows plastic and composite bearings to outperform metal in real-world applications, not just on paper.

TriStar’s engineered polymers and composites offer advantages that directly support reliability-focused design:

- Self-lubricating operation eliminates grease, oil, and contamination risks

- Predictable wear behavior, reducing sudden failures

- Low friction coefficients, improving efficiency and component life

- Vibration and impact damping, protecting surrounding components

- Corrosion and chemical resistance, enabling harsh-environment operation

- Low moisture absorption, maintaining dimensional stability

- High strength-to-weight ratios, supporting compact, flexible designs

- Regulatory-approved materials, including FDA- and food-grade options

Using The Right Materials to Build Better Equipment

The impact of bearing material selection extends beyond the bearing itself. Poor material choices can transfer heat, vibration, and electrical currents into surrounding components, causing failures that are difficult to diagnose.

TriStar frequently helps customers:

- Eliminate chronic vibration or noise issues

- Extend equipment service intervals

- Replace grease-dependent designs with maintenance-free alternatives

- Improve reliability without redesigning entire assemblies

When material selection is treated as an engineering decision, not a purchasing decision, performance improves across the entire system.

If you’re evaluating bearing materials for a new design, or troubleshooting a recurring failure, TriStar’s application engineers can help you identify the optimal polymer or composite solution. Contact us using the button below.