2 min read

Defined: Hydrophilic, Hydrophobic, Oleophilic, Oleophobic, Hygroscopic

When discussing advanced polymers and composite bearing materials you’ll often hear terms like hydrophilic, hydrophobic, oleophilic, oleophobic, and...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

To request compliance documentation click here.

2 min read

When discussing advanced polymers and composite bearing materials you’ll often hear terms like hydrophilic, hydrophobic, oleophilic, oleophobic, and...

3 min read

Cleaning can be a critical first step in many manufacturing processes, particularly for the medical, aerospace, and electronics industries. Proper...

1 min read

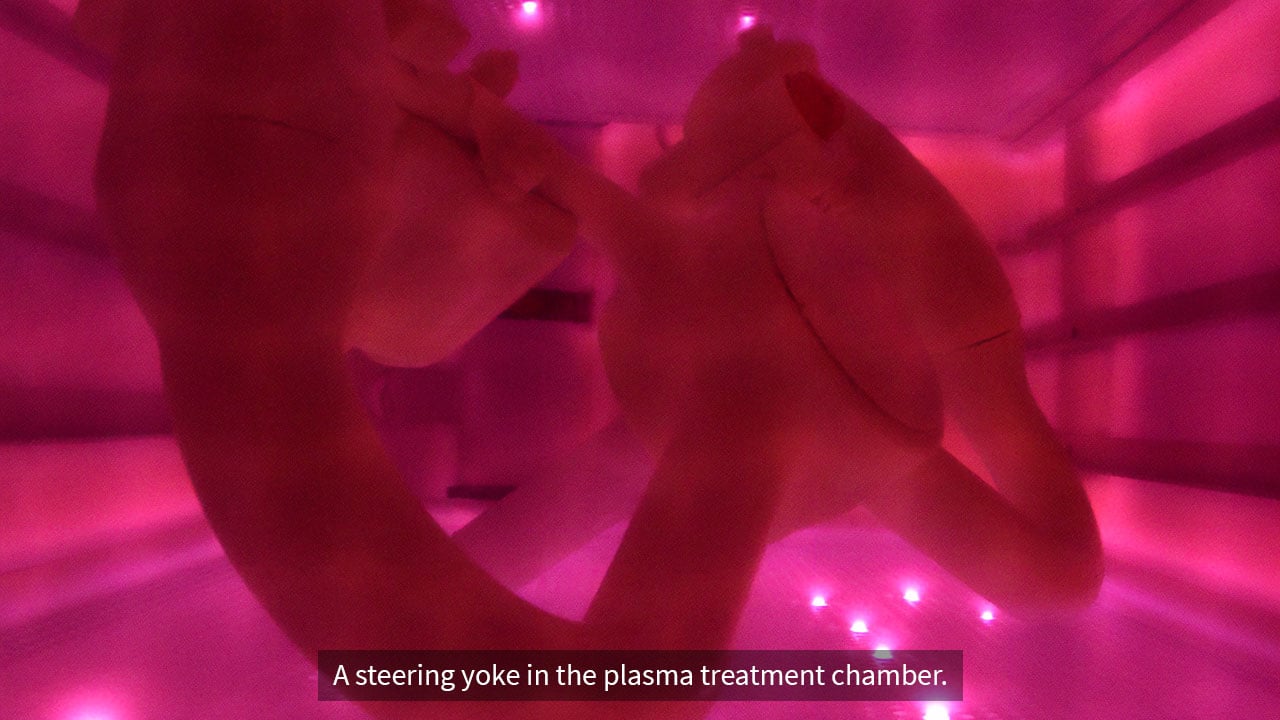

It’s a back-to-basics question, but one that we are asked often. Surface treatments are generally separated into two categories: atmospheric and...

1 min read

The US manufacturing economy continues to waver between marked improvement and ongoing challenge in 2016, according to the National Association of...

1 min read

Why should I choose parylene coating for my devices? This question was asked at a recent site visit, and I thought I’d share some quick facts about...

1 min read

Today we are talking films on Tech Talk ― as in corona treatment of ― not the latest “must- see” summer blockbuster (although we enjoy those, too!)....

1 min read

Measuring surface tension can be done quite easily in the lab with the use of a goniometer (or surface contact meter). In fact, this is a key service...

1 min read

We’ve had a few questions lately about the best method of bonding rubber to aluminum before overmolding. It seems this bonding combination poses a...

1 min read

Here’s a fishing tale about the one that didn’t get away! Our team worked with a high-end fishing manufacturer to design a whole new reel drag...

1 min read

We are often asked about which method is best for preparing fluoropolymers for a bonding application. The most critical step is bonding is to ensure...

1 min read

Question: How do I bond Delrin to other materials? Delrin (also known as Acetal, Polyocymethylene (POM), polyacetal, and polyformaldehyde) is an...

1 min read

Functional groups via plasma processing Here is a quick review of five gases that create polar entities on a polymer surface to render it hydrophilic...

1 min read

The growth of plastics in medical devices is growing exponentially around the world. Plastics are regulated like any other materials that may come in...