3 min read

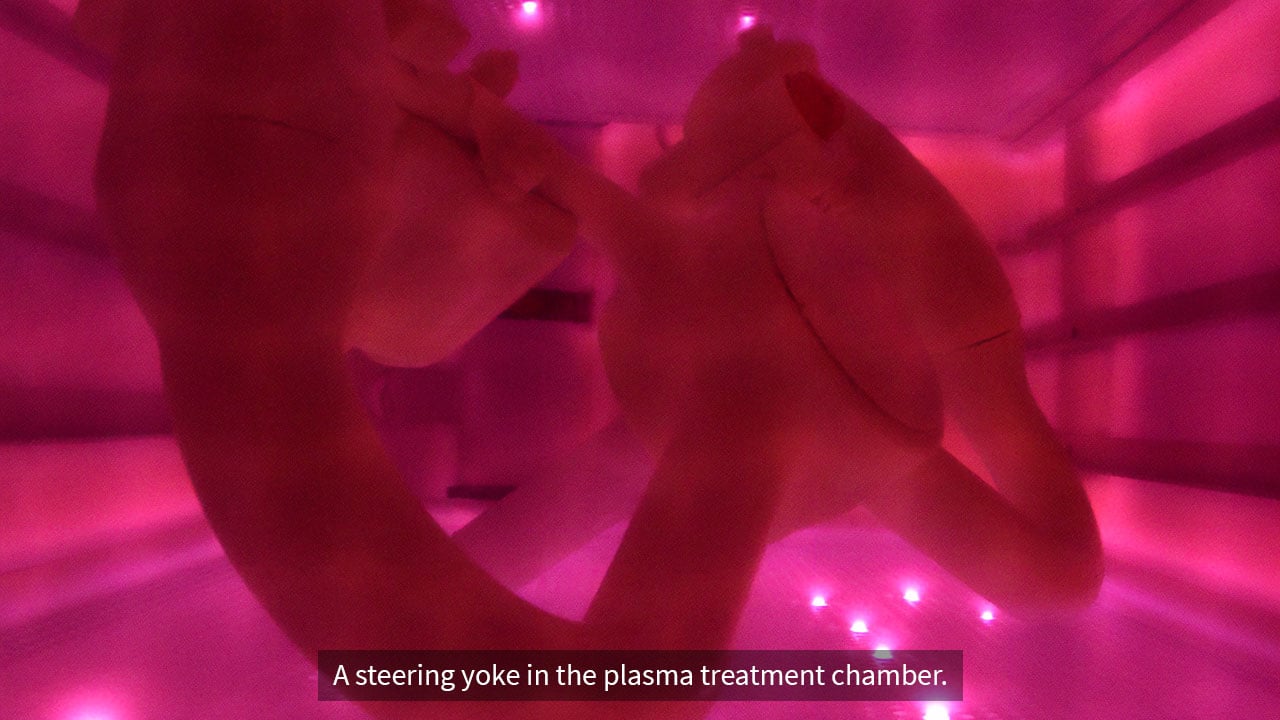

Cleaning Process Review: Plasma vs. Aqueous

Cleaning can be a critical first step in many manufacturing processes, particularly for the medical, aerospace, and electronics industries. Proper...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

To request compliance documentation click here.

3 min read

Cleaning can be a critical first step in many manufacturing processes, particularly for the medical, aerospace, and electronics industries. Proper...

2 min read

What are plasma surface treatments and how can they help materials and components perform their best in demanding applications? By altering the...

2 min read

There is usually a good correlation between bonding and wetting. Wettability can be defined as “the ability of a solid surface to reduce the surface...

2 min read

Good adhesion of manufactured parts. Whether you want to adhere one part to another, or secure paint to a component, good adhesion can be difficult...

1 min read

In honor of this recent commencement season, today we’re sharing a lesson right from our bearing resource center, TriStar University. Here’s a...

1 min read

It is no secret that medical manufacturers are turning to plasma treatment to help them improve the performance of their products. Whether used to...

1 min read

We’ve had a few questions lately about the best method of bonding rubber to aluminum before overmolding. It seems this bonding combination poses a...