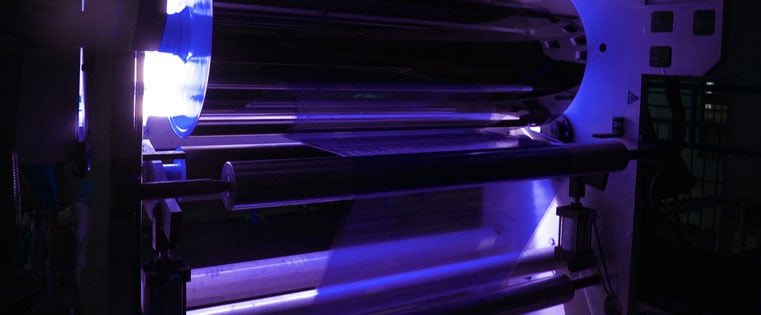

Today we are talking films on Tech Talk ― as in corona treatment of ― not the latest “must- see” summer blockbuster (although we enjoy those, too!). So what do you need to know about corona treatment and successful treatment of films?

As you probably know, corona treatment can help you modify plastic films and other materials to render them more bondable, or to provide a longer lifespan. Corona plasma is a visible electrical discharge which is produced when a high-voltage and high-frequency electric potential comes in close to electrodes in the atmosphere. When the discharge occurs, ions and ozone are generated; the ozone compound is relatively short-lived and may dissociate to molecular oxygen (O2) and oxygen radical (O`). The oxygen radical then works to modify the polymeric film material. Explore corona treatment and other techniques in the Surface Modification Technical White Paper.

While corona treatment has a very-high success rate, there are three common challenges to be aware of:

- Blocking – As polar groups form during corona, they have a high attraction to the molecular level, yet this attraction can be greater than the internal bonds of the substrate. Under these circumstances, the substrate can delaminate when the product is unrolled. The tighter the roll is wound and the longer it sits in storage, the more severe the problem becomes. Blocking is particularly challenging when working with films at the center of the roll.

- Heat Sealing - Excessive corona treatment can lead to problems when attempting to heat seal the product.

- Additives - If the polypropylene or polyethylene contains additional components (such as slip additives or some processing aids), the effectiveness of the initial treatment is reduced over time. This is caused as the additives “bloom” to the surface and partially mask the polar groups formed during treatment. To avoid this challenge, it is best to treat these films at the point-of-use rather than at the point-of-manufacture.

Beyond film, corona treatment is also applied to other in-line processes such as foils, paper, webs and tape. Will it work for your materials? Fill out a Surface Modification Worksheet with your design specs and we’ll help you find out!

Tell us about your experience with Corona Treatment of films in the comment field below. Or, if you’re so inclined, share your list of favorite summer films!