1 min read

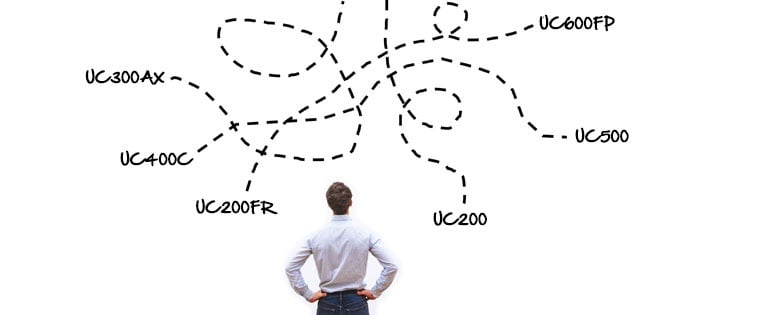

Ultracomp Grades Decoded

Ultracomp is a family of laminate wound bearing materials with migratory lubricants added to the resin system. All Ultracomp bearing materials are...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

1 min read

Ultracomp is a family of laminate wound bearing materials with migratory lubricants added to the resin system. All Ultracomp bearing materials are...

This question was posed to us from a manufacturer of small excavators, the kind you often see in the consumer rental market. Cast nylon is a good...