Oil and Gas Industry Equipment: Challenges for Critical Components

Table of Contents

- Oil and Gas Industry Overview

- Oil and Gas: Key Industry Categories

- Oil and Gas Industry Equipment: Component Engineering Challenges

- Case Studies: TriStar Polymer Material Success Stories in the Oil and Gas Industry

- Learning More: Engineering-Driven Component Selection for Oil and Gas Equipment

- Frequently Asked Questions

The oil and gas industry both literally and figuratively fuels the global economic engine.

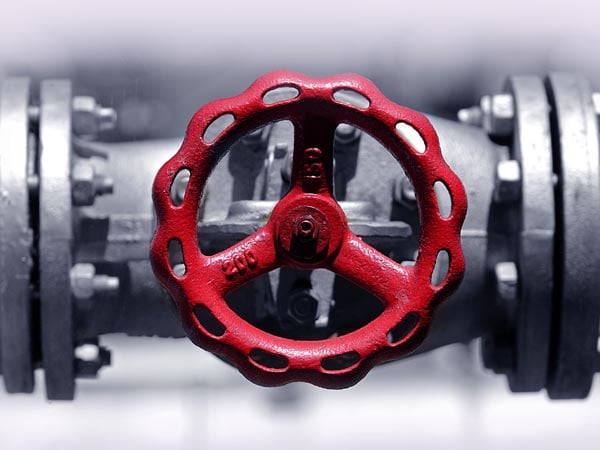

One of the largest industries in the world, oil/gas makes use of complex, specialized equipment across the entire supply chain. From extraction, to transportation, to refining and beyond, oil/gas operators and OEM’s are challenged to engineer equipment for success across a huge variety of applications; virtually all of it needs to perform in extremely challenging operating conditions. These conditions include high temperature, high pressures, caustic chemicals, and abrasive particulate matter.

All of this infrastructure is necessary for getting oil and gas out of the ground and processing it into final products used in a huge variety of industries. While the most obvious consumer-facing outlet for oil/gas products is gasoline and motor oil, products created by this industry are vital inputs for a plethora of other industries: chemical manufacturing, plastics, and pharmaceuticals, just to name a few.

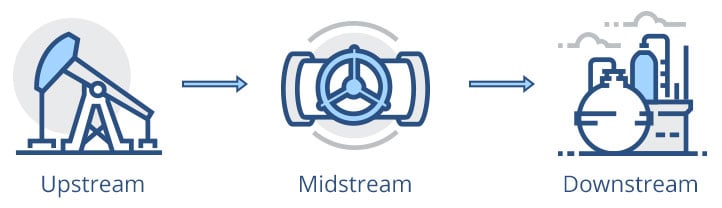

In this article, we provide an overview of key equipment used across upstream, midstream, and downstream oil/gas workflows.

Finally, we examine how TriStar’s advanced materials are used to manufacture components that address some of the most important engineering challenges for oil and gas equipment.

Prefer to read this later? We'll email you a PDF.

Oil and Gas: Key Industry Categories

Oil and gas production and processing requires a complex, multi-stage supply chain. This supply chain is typically divided into three segments: upstream, midstream, and downstream.

We cover each below. For an extremely detailed overview of the entire oil/gas production process, we recommend this guide here.

The corporate organization of these various industry segments varies. Some companies are specialized in extraction, refining, or pipeline operations, while others are integrated operators spread across all of these operational phases.

Upstream Oil and Gas: Extraction

“Upstream” refers primarily to the various techniques used to extract oil/gas from the earth. The precise extraction mechanism used depends on the underlying grade of oil (see below). Oil and gas extraction are distinct but closely related: in many cases, the release and capture of natural gas can occur during the oil drilling process. Gas is often dissolved in the oil itself.

“Upstream” refers primarily to the various techniques used to extract oil/gas from the earth. The precise extraction mechanism used depends on the underlying grade of oil (see below). Oil and gas extraction are distinct but closely related: in many cases, the release and capture of natural gas can occur during the oil drilling process. Gas is often dissolved in the oil itself.

What is the importance of oil/gas grades?

“Grade” refers to important chemical properties of oil/gas. These properties can vary based on where the media was extracted. For each of these grades, different operational procedures and equipment are required. For example, thicker, lower-grade oils may need to be refined at higher temperatures. Different grades also require different extraction techniques:

- Light and medium oil can flow naturally to the earth’s surface. From there, it can typically be extracted using vertical drilling and pumping.

- In some geographies, light oil can become trapped in non-porous rock (sometimes called “tight” rock; shale is one famous example). This situation calls for horizontal drilling and/or hydraulic fracturing (“fracking”).

- Heavy oil has a much thicker consistency and is more resistant to flowing. More advanced technologies are required to extract it.

How are different oil grades extracted?

The different grades discussed above require different extraction techniques. The most important categories for oil and gas extraction are “conventional” and “unconventional.”

- Conventional extraction refers to pumping from underground oil/gas reservoirs. Inside these reservoirs, oil sits as a liquid at normal atmospheric pressure. This fact means that it can flow through the well and into a pipeline without extensive additional processes at the extraction site. This simpler extraction process means lower costs at this stage. Conventional oil drilling can occur at either land-based or offshore drilling sites.

- Unconventional extraction refers to oil that cannot be extracted using traditional methods. For instance, oil sands contain oil that is mixed with thick particulate matter. This oil can be extracted using “sand mining” (where oil sands are mined directly and transported to a nearby crusher for separation) or “in situ recovery” (where advanced techniques achieve separation while the sands are still underground). The Canadian Association of Petroleum Producers provides a useful explanation of sand-based extraction here and one method for in situ recovery here

Upstream Oil and Gas Extraction Operations

Oil/gas wells are the first part of a huge arsenal of equipment used to get these commodities out of the ground, conduct preliminary processing, and prepare it for storage/transportation via the midstream segment. As noted above, the precise equipment used depends on the oil grade. The sheer variety of equipment used is too vast to cover here. We list some important examples below.

Example Oil/Gas Extraction Equipment

- Well Head

- Production and Test Manifolds

- Production Separators

- Metering and Storage Equipment

- Storage Tanks

- Pumps for both extracted media and support chemicals (Water, Glycol)

- Support Systems (HVAC, firefighting systems, air pumping systems, and more)

Midstream Oil and Gas: Storage and Transportation

Once oil and gas is safely out of the ground, it is ready for storage and/or transportation to refining facilities where it will be transformed into a salable product (or an intermediate product for use in another industry).

Once oil and gas is safely out of the ground, it is ready for storage and/or transportation to refining facilities where it will be transformed into a salable product (or an intermediate product for use in another industry).

Transporting Oil and Gas

Oil and gas are generally transported long distances via train, ship, or pipeline. There are some exceptions (for instance, freshly mined oil sands may be transported short distances by truck for processing).

Trains and ships offer more flexibility (pipeline’s delivery destinations are sharply constrained by their construction). Pipelines, however, offer lower transportation costs and lower risk of environmental contamination. These pipelines cover vast distances: the United States alone features over 2.6 million miles of pipelines that transport trillions of cubic feet of media every year. These massive volumes are simply beyond the capabilities of any other transportation method. Pipelines are found above ground, below ground, and even on the ocean floor.

The same pipelines transport gas/oil extracted and owned by many different companies. These quantities are separated by “pigs,” small vehicles designed to move within the pipeline itself. Pigs are used not only to separate products, but for cleaning and monitoring/preventive maintenance.

Downstream Oil and Gas: Product Refining and Distribution

This final industry segment focuses on the refining of oil and gas into various final and intermediate products, along with the sale and distribution of these products.

This final industry segment focuses on the refining of oil and gas into various final and intermediate products, along with the sale and distribution of these products.

Downstream Oil and Gas Operations: Refining

Once oil/gas have been extracted and transported, they are ready for refining. The precise refining process utilized depends on the end product: oil and gas are core inputs for a massive variety of products. Even among fuel products, different refining processes are used to create:

- Jet Fuel

- Vehicle Fuel

- Heating Oil

- Diesel Oil

- Fuel for electrical generation.

But these various grades of fuel are only the beginning of many end-uses for oil/gas.

What are examples of non-fuel oil and gas industry products?

The refining process creates intermediate chemicals which are then transported to the companies that turn these intermediates into final products.

- Asphalt - the roads we drive on using petroleum-based fuels are themselves made from petroleum.

- Plastics and Various Synthetic Materials - from packaging to vinyl home-siding.

- Chemicals - a vast array of “petrochemicals” are refined from oil. Natural gas is used in fertilizer, antifreeze, ammonia, and many more chemicals.

- Pharmaceuticals - even aspirin is made from benzene, a compound typically derived from petroleum.

- Consumer goods - CD’s, DVD’s and Lipstick are just a few examples.

- Clothing - polyester is a synthetic material found in clothes across the globe.

What are representative steps in the oil/gas refining process?

We cannot cover the specifics of the many different types of refining used for all of the product categories listed above. Below are some representative steps in petroleum refining. The U.S. Energy Information Administration provides an excellent, more detailed guide here.

- Separation: molecules are separated using atmospheric distillation. Oil is heated to high temperatures, causing it to vaporize so that it can be separated from other residual chemicals. A second-stage distillation process helps further separate various chemicals from the raw oil.

- Conversion: even after separation, heavy hydrocarbons remain. Oil is “cracked” to separate heavier and lighter molecules. That means the oil is again heated, this time with a special catalyst used to facilitate a chemical reaction.

- Treating: finally, fuel is treated to reduce molecules that are corrosive or prone to generating air pollution (sulfur is a prominent example). This process is also used to raise the octane levels of, for instance, automotive fuels.

Natural gas has its own unique refining requirements and processes. You can find an excellent overview here.

Oil and Gas Industry Equipment: Component Engineering Challenges

As the different industry segments discussed above indicate, the oil and gas industry relies on massive infrastructure featuring a huge arsenal of different types of equipment. While the engineering requirements of this equipment vary by application, certain challenges are commonplace.

As the different industry segments discussed above indicate, the oil and gas industry relies on massive infrastructure featuring a huge arsenal of different types of equipment. While the engineering requirements of this equipment vary by application, certain challenges are commonplace.

What are important challenges for oil and gas equipment components?

Components used in oil and gas industry equipment need to be carefully engineered to reflect demanding operating conditions. They need to meet these challenges to ensure both efficient operations and safety.

- High Temperatures: temperatures ranging up to 500 degrees Fahrenheit are commonplace in oil/gas applications. Components need to stand up to prolonged exposure to these temperatures without deforming or otherwise compromising performance.

- High Pressure: both oil and gas are pressurized for both transportation and a variety of refining processes. Components need to maintain performance in extremely high pressure operating conditions.

- Caustic Chemicals: from cleaning agents to sulfuric “sour” gas, the oil and gas industry is full of caustic chemicals. Components need to stand up to chronic exposure without compromising performance.

- Abrasive Environments: raw media often contains substantial amounts of sand and other abrasive particulate matter. Components used in the industry need to stand up to prolonged exposure to abrasion without compromising performance or lifespan.

- Reliability: the need for reliability in oil and gas components is two-fold. First, they cannot afford to fail: premature, unplanned failure comes with financial risk and real danger. Second, they need to minimize the need for maintenance work, both to limit cost and because many of these components are deep inside complex mechanisms that are not easy to reach for routine maintenance.

- Cost Effectiveness: some of the materials used in high-pressure/high-temperature environments are simply not cost-effective at the scale required by this massive industry. A component used as a one-off selection in aerospace may stand up to the requisite conditions but not be cost-effective in oil/gas, where a single plant or pipeline may require thousands.

How TriStar’s Self-Lubricating Components Help Address Oil and Gas Engineering Challenges

TriStar works directly with a variety of oil and gas companies to engineer components designed to thrive in challenging operating conditions.

TriStar Components Are:

- Ready for High-Temperature: our materials can be specified to perform at high temperatures, with numerous options even ready for the >500 degree Fahrenheit temperatures common in the oil/gas industry.

- Ready for High-Pressure: excellent strength-to-weight ratios helps our bearings stand up to high-pressure conditions without sacrificing reliability.

- Abrasion Resistant for Reliability in the Most Gritty Applications: Our materials have proven their ability to withstand high levels of abrasive particulate matter—like the sand and other grit found in many oil grades.

- Corrosion Resistant and Ready to Work with Caustic Chemical Media: TriStar bearings are designed to hold up in corrosive environments like oil/gas equipment (and even saltwater marine applications). Unlike metal or bronze components, TriStar’s materials resist virtually all corrosive materials; they will never rust, pit, or flake.

- Highly Reliable: our oil/gas materials offer exceptional reliability. Self-lubrication helps minimize maintenance while helping keep components in peak operating condition.

- Cost-Effective: TriStar components have proven their cost-effectiveness in oil/gas applications that require prices compatible with high-volume applications. They can offer exceptional performance characteristics while remaining price-competitive with other materials. Additionally, self-lubrication helps minimize maintenance costs and improve reliability for maximum efficiency.

Example TriStar Materials Used in Oil and Gas Industry Applications

- CJ Composite: Composite bushings offer an upgrade on standard, metallic bushings. TriStar CJ bushings have an extensive history of zero failures in oil and gas applications.

- Ultraflon: we engineer steel-backed glass/PTFE lined bushings to provide similar performance as our CJ composite in severe service (500°F) applications.

- Engineering Thermoplastics: PEEK and Rulon perform well in elevated temperature applications (350 °F) and provide long life reliability in low-pressure, low-load conditions requiring corrosion resistance. Rulon and PEEK will maintain their mechanical properties at elevated temperatures (350 °F) for thousands of hours.

For a deeper look at specific material specifications, access our interactive materials database using the button below.

Case Studies: TriStar Polymer Material Success Stories in the Oil and Gas Industry

The case studies below help illustrate the diversity of solutions TriStar materials have offered throughout the oil and gas industry. In each case, we carefully studied the cost and performance requirements of the application at hand. With this knowledge in place, we were ready to draw on our deep lineup of polymer and composite materials to deliver the optimal component. When necessary, we can create custom formulations to fulfill exacting operational requirements.

Upstream Oil and Gas Success Stories

Upstream Materials Success Story One: Custom Seal Designs for Fracking Powertrains

The Client: A fracking equipment manufacturer.

The Client: A fracking equipment manufacturer.

Challenge: Fracking powertrains are operated 24/7/365 and require ultra-reliable transmission designs. Our customer needed a custom rotating shaft seal design to elevate industry expectations for transmission efficiency.

Solution: Our engineers studied a 1960’s-era auto transmission design for inspiration. A simple change in seal materials on the powertrain allowed for superior uptime and improved equipment performance. This case is a paradigmatic example of new materials allowing vintage design principles to drive improved ROI for mission-critical equipment.

Upstream Materials Success Story Two: High Temperature Phenolic Thrust Washers for Electric Submersible Pumps

The Client: A leading oil field services provider with global operations.

The Client: A leading oil field services provider with global operations.

Challenge: Phenolic thrust washers were overheating when operating during pumping. Temperatures increase as the well runs deeper, and these washers were operating in an environment that often exceeded 300 degrees fahrenheit.

Solution: TriStar studied the application and identified Rulon 945 as the right material for the application. This Rulon formulation is able to withstand 300 degree plus temperatures. It takes advantage of a proprietary filler system which enables flexible operation in both high- and low-temperature applications.

Upstream Materials Success Story Three: Environmentally Friendly Materials for Liner Hangers | Combining Competitive Cost and Advanced Performance

The Client: An OEM offering a variety of oil and gas completion solutions.

The Client: An OEM offering a variety of oil and gas completion solutions.

Challenge: Legacy materials for liner hanger designs were no longer available due to environmental issues. Many modern alloys, coatings, and composites were capable of solving the environmental issue and performance requirement, but they were all proving too costly for this consumable component.

Solution: TriStar’s Ultracomp family of products finally hit the sweet spot for an alternative modern material. Ultracomp achieved environmental compliance, advanced composite performance, and a cost structure appropriate for a high-volume consumable.

Upstream Materials Success Story Four: A Cement Tool That Generated Savings Without Sacrificing Performance

The Client: An expert oil and gas completions provider.

The Client: An expert oil and gas completions provider.

The Challenge: Cement tools are essential products for constructing well casings. These tools cannot be retrieved or reused. Conventional iron and steel tools were proving too expensive for this consumable application, in addition to being difficult to transport.

The Solution: TriStar analyzed the functional requirements of the casings and provided our CJ filament wound family of products as a more cost effective alternative. Our CJ material brought the requisite strength alongside a substantial cost advantage.

Upstream Materials Success Story Five: Beating Bronze in Offshore Drilling Equipment

The Client: Offshore drilling equipment manufacturer.

The Client: Offshore drilling equipment manufacturer.

Challenge: a major offshore drilling OEM needed a better material for their drill line spoolers—the spools which control hauling of cable lines. They had traditionally employed bronze but needed a more durable and clean, environmentally friendly option.

Solution: we identified our CJ composites as the right solution. This material does not compromise on strength compared to traditional metal options and can easily handle the required loads and shocks. It will never corrode, even with chronic saltwater exposure. And self-lubrication means grease-free operation, essential in environmentally sensitive marine environments.

Midstream Oil and Gas Success Stories

Midstream Materials Success Story One: Stronger Flange Bearings for a High Rotation, High Load Application

The Client: A leading OEM for midstream measurement solutions.

The Client: A leading OEM for midstream measurement solutions.

Challenge: Existing flange bearings for compact provers lacked the required mechanical properties, exhibiting cold flow deformation at high loads and RPM’s.

Solution: TriStar recognized this problem as a common issue with unfilled PTFE under sustained rotational stress. We solved the problem with our Rulon AR and Rulon LR materials, which use a filler system which reduces cold flow and enables enhanced efficiency for prover systems.

Midstream Materials Success Story Two: A Designed-to-Specification Material for Cost-Effective Compressor Piston Rings

The Client: An OEM offering a variety of oil and gas equipment solutions.

The Client: An OEM offering a variety of oil and gas equipment solutions.

The Challenge: find the right material that could support competitive prices for the piston rings used in after-market compressor parts. This application would require long periods of high-load runtime.

The Solution: Saint-Gobain has decades of experience formulating compounds for resilience to high wear. They engineered a product specifically to thrive in this application: Rulon 945. This is a black PTFE material that has the lowest deformation under load of all of the Rulon grades and it's an ideal choice for high-demand thermal applications, or anywhere excellent chemical resistance and good dimensional stability are required.

Downstream Oil and Gas Success Stories

Downstream Materials Success Story One: A Longer Lasting, More Accurate Material for Diaphragm Meters

The Client: An OEM offering solutions across a wide variety of oil/gas applications.

The Client: An OEM offering solutions across a wide variety of oil/gas applications.

Challenge: The legacy material used in diaphragm meters had inadequate lubricity for long life in high-wear applications. Preserving component lifespan and accuracy was an essential requirement for the commercial metering marketplace.

Solution: TriStar supplied Rulon LR, leveraging its proprietary filler system to provide enhanced dimensional stability. This advantage translated to optimal performance even after sustaining long periods of high-wear use, enabling high accuracy and cost-effective longevity.

Downstream Materials Success Story Two: A More Cost-Effective, Less Bulky Pipe Centralizer Material That Reduced Install Times

The Client: Pipe Centralizer OEM

The Client: Pipe Centralizer OEM

The Challenge: legacy materials for pipe centralizers were bulky, requiring excessive quantities to complete each job. In addition to being hard to work with, these materials’ cost structure was becoming bulky as well.

The Solution: TriStar’s Ultracomp UC300AX offered an ideal solution. The Ultacomp family of products feature industry-leading compressive strength and abrasion resistance alongside exceptional lubricity. These attributes reduce the total square feet of material required. In this application, Ultrcomp managed to reduce install, time, transportation cost, and overall material costs.

Learning More: Engineering-Driven Component Selection for Oil and Gas Equipment

We hope this guide has provided useful insight into how TriStar’s self-lubricating materials can help enhance component performance in highly demanding oil/gas applications. In our experience, the right materials selection can help tackle some of the biggest challenges for both oil/gas operators and OEM’s.

We hope this guide has provided useful insight into how TriStar’s self-lubricating materials can help enhance component performance in highly demanding oil/gas applications. In our experience, the right materials selection can help tackle some of the biggest challenges for both oil/gas operators and OEM’s.

At the same time, we never present any of our materials as an all-encompassing solution. To maximize performance, reliability, and efficiency, materials need to be selected based on careful engineering analysis of the projected operating environment.

All too often, bearings and similar vibration- and impact-absorbing components are approached as commodities and sourced from the cheapest bidder. Over the long term, we think an engineering-driven approach to component selection almost always pays off. In many cases, our components are directly price-competitive with traditional metal solutions. In others, they are similarly priced but offer substantial operational benefits that bring far greater lifespan ROI. Oil/gas is a great example of an industry where the cost of failure can be extremely high and a well-engineered component based on the right materials can make all the difference.

To help engineer the right materials solutions, TriStar brings a true consultative engineering approach to our relationship with every client. We work hard to understand not just where materials can function, but where they can solve problems and help equipment work better than ever.

If you have questions about how our advanced composite and polymer materials can tackle engineering challenges for your oil/gas equipment, please reach out to our team using the button below.

Frequently Asked Questions

Here are a few common questions relating to the content in this guide.

Q: What materials perform best in oil and gas applications?

A: Rulon®, Ultracomp®, and TriSteel™ are top-performing materials in oil and gas settings. These self-lubricating polymers withstand pressure, temperature swings, and chemical exposure while reducing maintenance and preventing metal-on-metal contact.

Q: How do self-lubricating bearings help oilfield equipment?

A: Self-lubricating bearings eliminate the need for external grease or oil, making them ideal for remote and harsh environments. They resist corrosion, survive dry runs, and reduce wear under high load and temperature conditions.

Q: What are the challenges of upstream oil and gas equipment?

A: Upstream equipment like pumps and BOPs (Blowout Preventers) faces abrasive fluids, high pressure, and dynamic loading. Components must survive constant motion and extreme environments without seizing or degrading.

Q: Why is material selection critical in midstream operations?

A: Midstream systems experience wide temperature swings and require consistent low-friction performance. TriStar materials maintain dimensional stability and reduce downtime during transport and storage.

Q: What demands do downstream refineries place on components?

A: Downstream refining involves chemical exposure, tight tolerances, and reliability requirements. Self-lubricating parts like valve seats and wear rings reduce failure risk and extend service life.

Q: How does TriStar support OEM design teams?

A: TriStar collaborates with OEMs to recommend polymers based on load, temperature, PV, and chemical conditions. Custom parts are machined or molded to exact oil and gas specs.

Q: What component types are most commonly replaced in oil and gas?

A: Common replacements include bearings, bushings, valve seats, wear rings, and seals—especially where metal parts fail under friction or corrosion.

Q: What are the benefits of TriStar’s composite materials?

A: Composite materials reduce friction, resist galling, and maintain strength across temperature ranges. They also eliminate the need for wet lubrication in remote or sealed systems.

Q: Does TriStar serve both new design and MRO markets?

A: Yes, TriStar supports both new equipment design and maintenance/repair operations (MRO) for North American oil and gas manufacturers.

Q: Are TriStar materials tested for harsh oilfield conditions?

A: TriStar’s materials have been field-tested in extreme applications like subsea BOPs and cryogenic LNG systems, proving durability under thermal cycling and chemical exposure.