2 min read

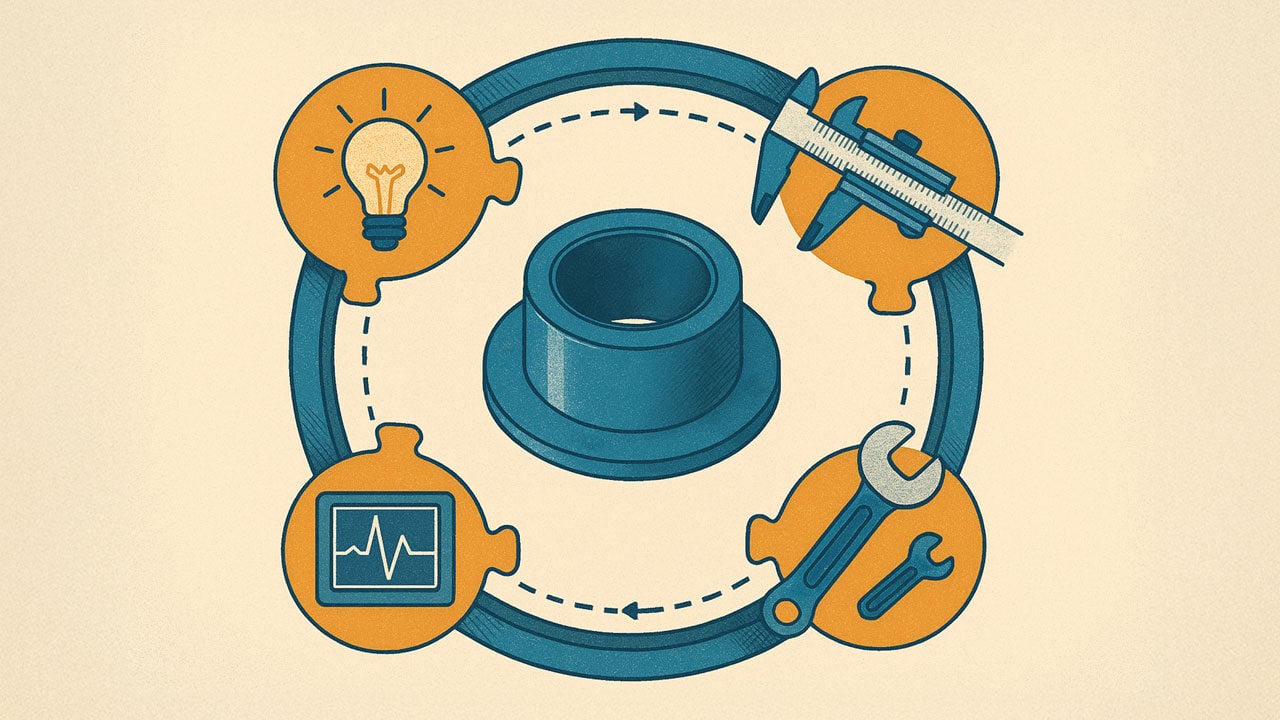

An All-Phase Commitment to Value-Added Engineering

At TriStar, engineering support is not something customers need to request separately. From early application reviews to long-term troubleshooting,...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

To request compliance documentation click here.

2 min read

At TriStar, engineering support is not something customers need to request separately. From early application reviews to long-term troubleshooting,...

2 min read

In complex mechanical systems, bearings are often treated as routine parts: small, commoditized, and easy to replace. But in many cases, they “bear”...

3 min read

TriStar’s Enhanced Materials Division (EMD) offers advanced technologies like plasma surface treatment and specialized polymer filtration membranes....

2 min read

The market for bearings and similar components like bushing and shock absorbers is multi-faceted. On one hand, a variety of non-specialized,...