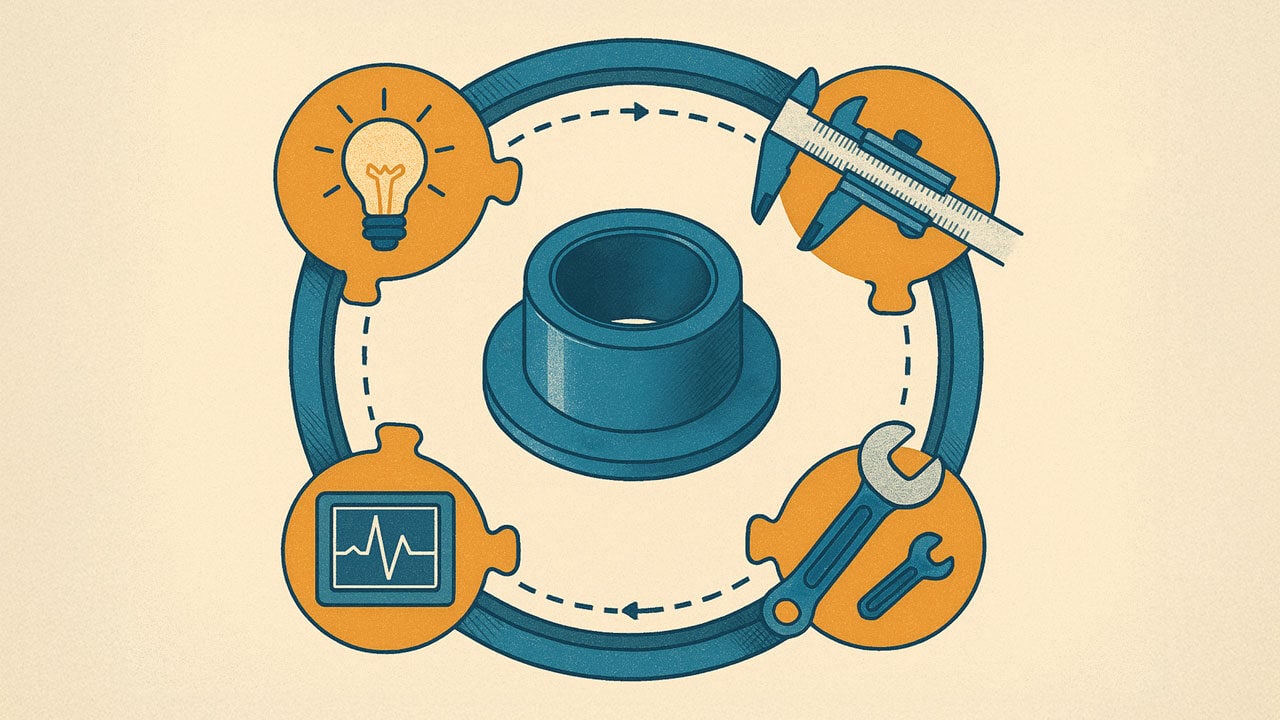

At TriStar, engineering support is not something customers need to request separately. From early application reviews to long-term troubleshooting, our team is structured to provide engineering insight at each step. This commitment applies whether someone is ordering a single bearing or developing a complex new system.

Our value-added engineering isn’t a line item or an extra service tier, but a cultural foundation for how we work. Whether a customer is simply ordering an off-the-shelf material through a distributor or searching for a fix a seemingly unsolvable issue, our engineering team is involved from the beginning.

This approach helps customers make more informed decisions, prevent avoidable issues, and get stronger results from their investment in high-performance polymer components. And it’s one of the biggest reasons customers choose TriStar.

Early-Stage Support: Asking the Right Questions

TriStar's engagement starts with listening. When a customer first reaches out, the sales team works closely with engineering to ask the right questions about the application, operating conditions, and material expectations. We go beyond simply filling out order forms and take preemptive steps to check that a part will be ready for the specific task it will be asked to perform.

As part of this process, customers are asked to complete a structured engineering worksheet. These worksheets guide the discussion and ensure that all relevant details (like mating materials, temperature ranges, and load types) are captured upfront. In some cases, a TriStar engineer will visit the customer’s facility to better understand how the part fits into the full system.

For customers switching from metal components to polymers, this early support is especially important. Polymers behave differently under load, heat, and motion. Many customers are not familiar with what these materials can do—or what their limitations are. TriStar helps bridge that knowledge gap.

Bag, Tag, and Beyond: A Guiding Hand When Facing Unknowns

Some of the most valuable engineering support TriStar provides begins with uncertainty: a part is failing, performance is off, or sourcing has become impossible—and there’s no drawing, no spec sheet, and no clear next step.

In these moments, customers don’t just need a catalog of advanced materials. They need a partner who can help them make sense of the challenge at hand.

Even if all you have is a worn component pulled from a machine, TriStar can help you get started. Bag it, tag it, and send it in: we’ll identify the material, assess the wear, and work with you to define what the replacement needs to do and how to make it better.

This is just one way we support customers who may not know what questions to ask or what failure signs to look for. With in-house testing capabilities, a structured evaluation process, and experienced engineers who know where to dig, we help teams navigate uncertainty and move toward a solution with clarity and confidence.

Consultative Material Selection

At TriStar, material selection is not a simple transactional decision, but an in-depth discovery process. What may start as a straightforward sourcing request often turns into a more nuanced engineering conversation. As we work through the details (whether through worksheets, testing, or onsite collaboration) new engineering challenges and opportunities are likely to emerge.

The resulting insights often lead to improved choices. This level of consulting engineering support is designed to not just avoid common causes of bearing failure, but drive better outcomes long-term through purposeful engineering strategy (even helping customer solve problems they didn’t know they had).

Long-Term Engineering Engagement

Once a part is delivered and installed, TriStar’s involvement doesn’t stop. Our engineering team remains available to help evaluate performance, identify root causes of wear or failure, and make refinements as needed.

In some cases, we also assist with redesigns when customers upgrade their systems or need to scale production. Access to engineering support through a proven relationship makes it easier for customers to adapt to the necessary changes quickly and confidently.

Built-In Support That Scales with Your Needs

TriStar’s engineering support is integrated with every project, whether you’re sourcing a standard part or solving a complex performance issue. For a closer look at how our all-phase approach works in practice, download our Guide to Engineering Services for High-Performance Bearings, which provides some real-world examples and insights from the TriStar team.

Frequently Asked Questions

Q: What is value-added engineering at TriStar?

A: Value-added engineering at TriStar is a collaborative process that enhances product performance, manufacturability, and reliability. It includes material selection, prototyping, testing, and ongoing support to deliver better long-term results while minimizing costs and delays.

Q: How does TriStar’s value-added engineering process reduce design risk?

A: TriStar’s value-added engineering process identifies potential design flaws early through real-world testing, simulation, and expert review. This reduces costly late-stage changes, lead times, and field failures.

Q: What engineering services are included with TriStar’s support?

A: TriStar offers application engineering, materials consulting, custom fabrication, and in-house testing. These services are integrated into every phase of the value-added engineering process.

Q: What types of testing does TriStar offer?

A: TriStar provides real-world performance testing, simulation modeling, and failure analysis. These tools help validate design decisions and optimize components for real operating conditions.

Q: How does TriStar help with bearing material selection?

A: TriStar engineers guide clients through optimal bearing material choices based on application loads, motion, temperature, and environment. Support includes metal-to-polymer upgrades and hybrid options.

Q: What industries benefit most from TriStar’s value-added engineering?

A: Aerospace, food processing, energy, and other industries benefit from TriStar’s application-driven approach, especially where performance, compliance, and durability are critical.

Q: What’s the difference between value-added engineering and standard sales support?

A: Unlike standard sales assistance, value-added engineering integrates engineering insight across the product lifecycle—from design to field support—to improve total system outcomes.

Q: Can TriStar support both custom and off-the-shelf solutions?

A: Yes, TriStar’s value-added engineering supports standard and fully custom solutions, offering flexibility based on project needs, timelines, and budget.

Q: Why is post-sale engineering support important?

A: Post-sale support ensures components perform as expected and includes diagnostics, failure analysis, and continuous improvement opportunities.

Q: Is TriStar’s engineering optimized for North American markets?

A: Yes, all solutions are developed with North American compliance, performance expectations, and industry standards in mind.