3 min read

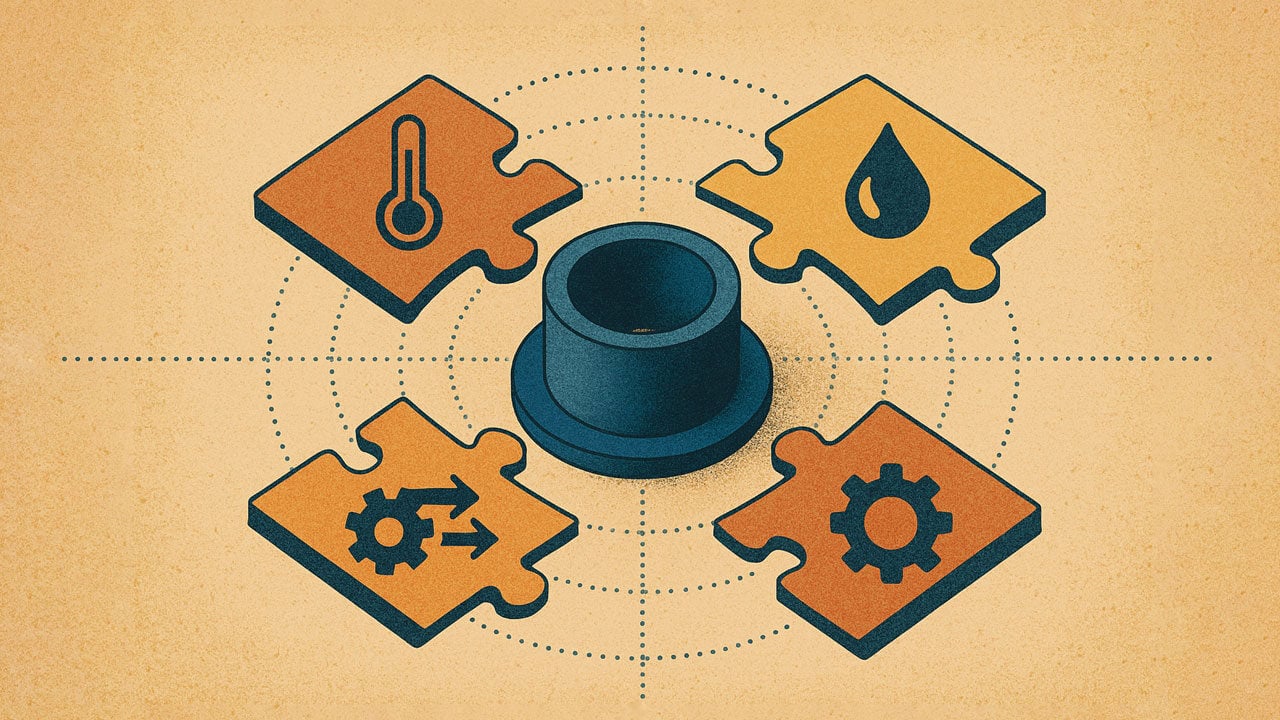

Why Context is Key for Advanced Polymer Components

When it comes to high-performance bearing materials, there’s no such thing as a one-size-fits-all solution. From wear and friction to chemical...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

To request compliance documentation click here.

3 min read

When it comes to high-performance bearing materials, there’s no such thing as a one-size-fits-all solution. From wear and friction to chemical...

3 min read

The market for bearings and similar components like bushing and shock absorbers is highly-fragmented and multi-faceted. On one end of the spectrum...