The pulp and paper industry’s market is changing, but it remains robust:

“If you thought the paper industry was going to disappear, think again. Graphic papers are being squeezed by digitization, but the paper and forest-products industry overall has major changes in store and exciting prospects for new growth.”

– McKinsey Report on Pulp and Paper Industry Outlook

This blog looks at key pulp and paper industry trends heading into the next decade.

3 Important Trends in the Pulp and Paper Industry

- Adapting to New Market Realities: the move from graphic papers to packaging.

- Anti-Plastic Consumers Could Drive Continued Packaging Growth

- Accelerated investment in processing capabilities for recycled materials.

The main article below is part of our series of articles focused on key challenges for pulp and paper equipment manufacturers (you can read our main guide on that topic here).

Pulp and Paper Industry Trend One: Adapting to New Market Realities

The proliferation of digital technology at both home and work has dramatically decreased overall demand for “graphic papers.” This category includes paper products like regular printer paper, newsprint, and the glossy paper used for magazines and brochures. We are moving away from a “paper world” for day-to-day communication, and this clear trend may lead casual observers to assume the pulp-and-paper industry is in decline. After all, in 2015, overall demand for graphic paper products fell for the first time in recorded history.

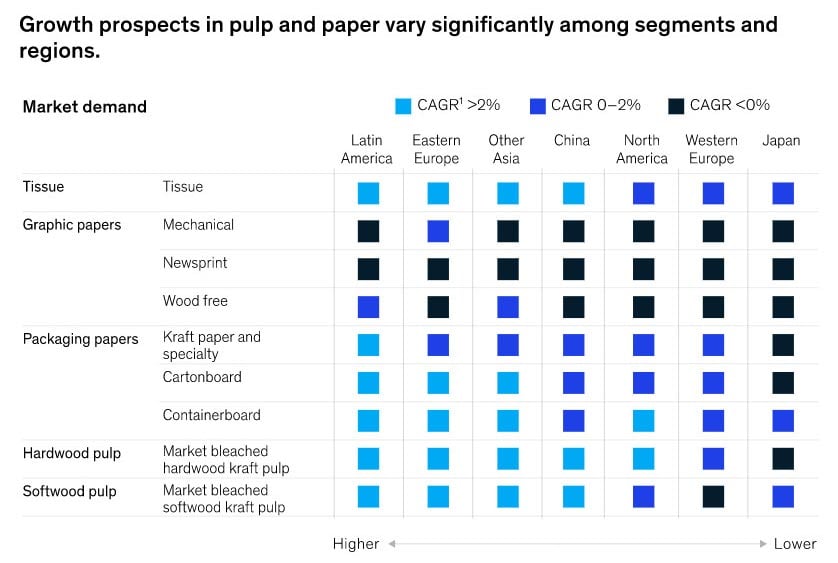

But this assumption is false. Graphic paper is just one of many products processed from wood pulp, and other markets continue to exhibit strong demand growth. One of the most important pulp and paper industry trends is the aggressive pivot toward growth markets like packaging material.

As the graph below demonstrates, growth in areas like cartonboard, containerboard, and tissue paper will be instrumental to “papering over” revenue losses stemming from the global reduction in graphic paper use.

Infographic Source: McKinsey Pulp and Paper Report

Pulp and Paper Industry Trend Two: Anti-Plastic Consumers Could Drive Continued Packaging Growth

Paper-based packaging products offers marked environmental advantages over plastics: they are readily biodegradable, do not accumulate in the ocean, and can be readily composted or repurposed.

As environment-conscious consumers ramp up pressure for a reduction in plastic packaging, pulp and paper manufacturers will benefit. This trend should help give long-run fuel to the market trend described in Trend One—a move away from plastic packaging will help ensure that packaging is not just a replacement for lost graphic paper demand, but a viable long-term growth market.

Pulp and Paper Industry Trend Three: Recycled Products

The American Forest; Paper Association reports that “65.7% percent of paper consumed in the United States was recycled in 2020...nearly the double the rate the U.S. paper industry achieved in 1990.” Growing environmental concerns and consumer activism have led to consistent increases in the use of recycled materials in the pulp and paper industry.

Adaptation requires innovation both in products (learning how to use recycled materials in marketable products) and processing (recycled materials require a different approach than raw wood chips). Indeed, we are already seeing US pulp and paper companies make major investments in recycled material mills, such as this $125 million facility in Pennsylvania.

Learn About Key Challenges for Pulp and Paper Equipment Manufacturers

In our experience, pulp and paper industry applications are typically best served by carefully engineering materials and components to reflect specific operating challenges. Caustic chemicals, large quantities of water, abrasive media, vibration, and high-heat are all daily working realities for pulp and paper firms, and any of these issues can degrade components made from the wrong materials.

We take a deeper look at some of these challenges in our in-depth guide here (also available as a free whitepaper PDF at for offline reading):