3 min read

TriSteel Self-Lubricating Bearings for Automotive Applications

![]() Dave Biering

November 15, 2021

Dave Biering

November 15, 2021

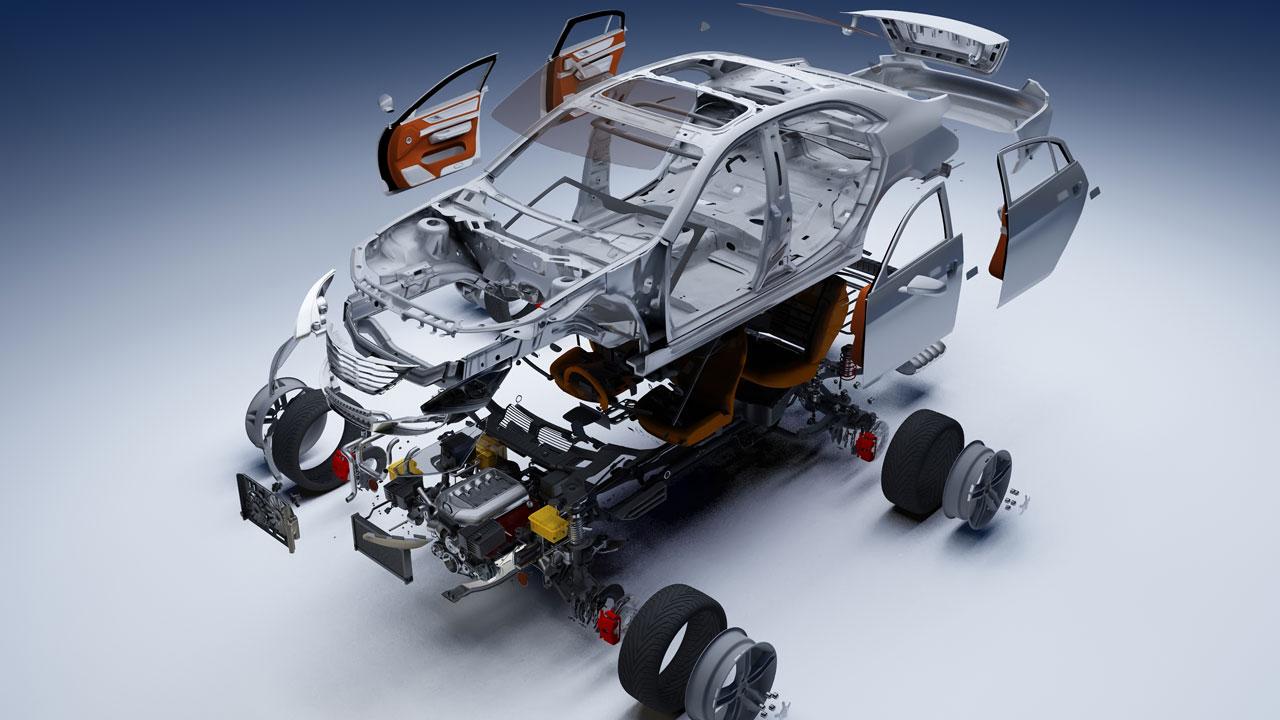

Auto design manufacturers are constantly seeking innovative solutions to improve vehicle safety, reliability, and performance. Today’s advanced automotive systems such as 4-wheel drive controls, CVTs (continuously variable transmissions), clutch systems, and dual-mass flywheels require precision components that can withstand high stress, temperature, and vibration.

TriSteel self-lubricating bearings from TriStar Plastics are engineered to excel in these demanding environments, offering maintenance-free performance, long wear life, and superior vibration resistance.

How TriSteel Bearings Are Engineered for Automotive Demands

TriSteel bearings feature a dual-layer design, offering flexibility in outer-shell materials (steel, stainless steel, or bronze) and inner polymer liners that are self-lubricating and dry-running. This structure allows for a customized bearing solution that meets specific mechanical and thermal requirements in automotive design.

- Dual-layer design: Provides multiple options for outer-shell structural support and low-friction polymer liners tailored to performance and load.

- Self-lubricating liners: Eliminate the need for external grease, enabling oil-free, maintenance-free operation that reduces maintenance intervals and total lifecycle costs.

- High side-load tolerance: Exceptional capacity for managing axial and radial stresses in rotary and oscillating automotive components.

- Temperature and chemical resistance: PEEK/stainless-steel TriSteel bearings perform reliably in high-temperature environments, valves, and pumps that experience chemical exposure.

- Vibration resistance: Ideal for undercarriage and suspension systems, where continuous impact and movement demand consistent friction performance.

Expert Note from TriStar: TriSteel’s metal-backed, polymer-lined design represents the best of both worlds: the strength and rigidity of metal combined with the low-friction, self-lubricating benefits of engineered polymers. This structure makes TriSteel an ideal replacement for greased bronze bushings in applications where access for relubrication is difficult or impossible.

Why Self-Lubricating Bearings Matter in Automotive Engineering

Automotive systems operate in harsh, variable conditions; they’re constantly exposed to high loads, heat, and environmental contaminants. In such conditions, traditional greased bearings often fail prematurely due to lubricant migration, contamination, or maintenance neglect.

By contrast, self-lubricating bearings integrate solid lubricants (PTFE, graphite, or other additives) directly within the polymer liner, creating a transfer film on the mating surface that provides consistent, low-friction operation over the product’s entire life cycle.

Key benefits of self-lubricating bearings in automotive design include:

- Reduced maintenance: No relubrication required, perfect for sealed or inaccessible systems.

- Cleaner operation: No risk of grease contamination in sensitive drivetrain assemblies.

- Improved reliability: Stable friction levels under varying temperatures and loads.

- Longer component life: Less wear on both the bearing and the shaft, extending service intervals.

Expert Note from TriStar: Tristar’s self-lubricating solutions are widely adopted in automotive, aerospace, marine, and industrial markets because they deliver consistent performance even under extreme duty cycles. For automotive engineers focused on longevity and reliability, switching to TriSteel bearings can translate to thousands of hours of maintenance-free operation and measurable gains in efficiency.

TriSteel Bearings in Action: Automotive Applications

1. Transmission and Drivetrain Systems

TriSteel bearings deliver stable, friction-controlled motion within CVT assemblies, clutch actuators, and flywheel damping systems, ensuring precise torque transfer and minimal energy loss.

2. Suspension and Steering Components

Their excellent shock and vibration resistance make TriSteel ideal for steering linkages, undercarriage joints, and suspension arms that experience constant movement and load changes.

3. Engine and Pump Assemblies

With PEEK/stainless combinations, TriSteel bearings maintain performance in high-temperature and chemically aggressive environments, including fuel pumps and cooling systems.

4. Electric Vehicle Platforms

In EV applications, where quiet operation and efficiency are critical, TriSteel bearings’ low noise and dry-running behavior support smoother, cleaner motion across battery systems and electric motor housings.

Expert Note from TriStar: TriStar’s engineering team collaborates directly with automotive OEMs to tailor bearing solutions to specific material, load, and environmental requirements. Whether it’s reducing NVH (Noise, Vibration, and Harshness) in EV platforms or improving thermal performance in powertrain components, TriSteel bearings are engineered to meet the future of mobility.

Why Automotive Manufacturers Trust TriStar Plastics

For over 40 years, TriStar Plastics Corp. has been a trusted partner to automotive engineers worldwide, providing customized bearing and wear solutions that improve product reliability and simplify assembly.

What sets TriStar apart:

- In-house material science expertise: Deep understanding of PTFE, PEEK, and composite materials.

- Custom fabrication services: Ability to produce standard and non-standard bearing sizes with short lead times.

- Engineering support: Application review, PV calculations, and material recommendations tailored to your system’s duty cycle.

- Proven industry track record: TriStar’s products are trusted by major OEMs across automotive, aerospace, and heavy equipment sectors.

Expert Note from TriStar: Every bearing application tells a story. TriStar’s approach begins with understanding the customer’s specific performance challenges, whether it’s reducing maintenance in fleet vehicles or extending life in undercarriage systems. Our customer-centric engineering process ensures each TriSteel bearing delivers reliability, consistency, and measurable ROI.

Next Steps

Interested in exploring TriSteel self-lubricating bearings for your next automotive project?

- Contact our engineering experts to discuss your design requirements.

- Explore our TriSteel Application Case Studies to see how real-world manufacturers have improved uptime and reliability.