1 min read

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

1 min read

![]() Dave Biering

September 30, 2014

Dave Biering

September 30, 2014

Measuring surface tension can be done quite easily in the lab with the use of a goniometer (or surface contact meter). In fact, this is a key service of TriStar’s Surface Modification Division.

The process begins by first measuring the baseline contact angles to determine the right surface modification method. Since the surface tension of liquids and the surface energy of materials must be matched, we add a droplet of water to the component to get the best reading.

The component is then placed in a vacuum plasma chamber, treated, and read again to measure tension changes. After plasma cleaning, components are much more accepting of secondary treatments such as adhesion, ink stamping, overmolding and more. If the surface energy of the material is too low, then the coatings will not flow well and fisheyes, pinholes, gaps, or air bubbles will form. If the material surface energy is too high, then paints, inks and other coatings may bleed or be difficult to control. So accuracy is key!

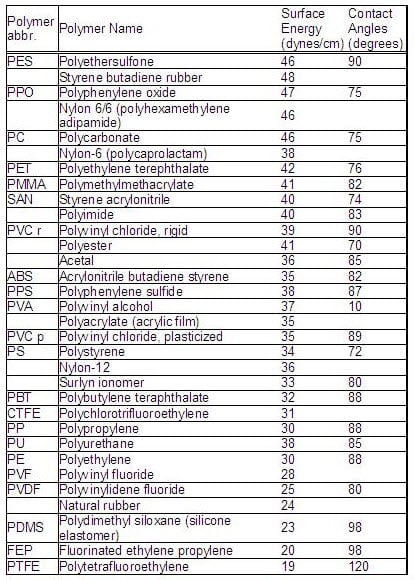

Here’s a chart to help you review the different variables of untreated polymers:

You might also want to check out this video for a demonstration (below), or feel free to reach out to the Surface Modification Experts!