2 min read

What are Fluoropolymers and What are their Common Attributes

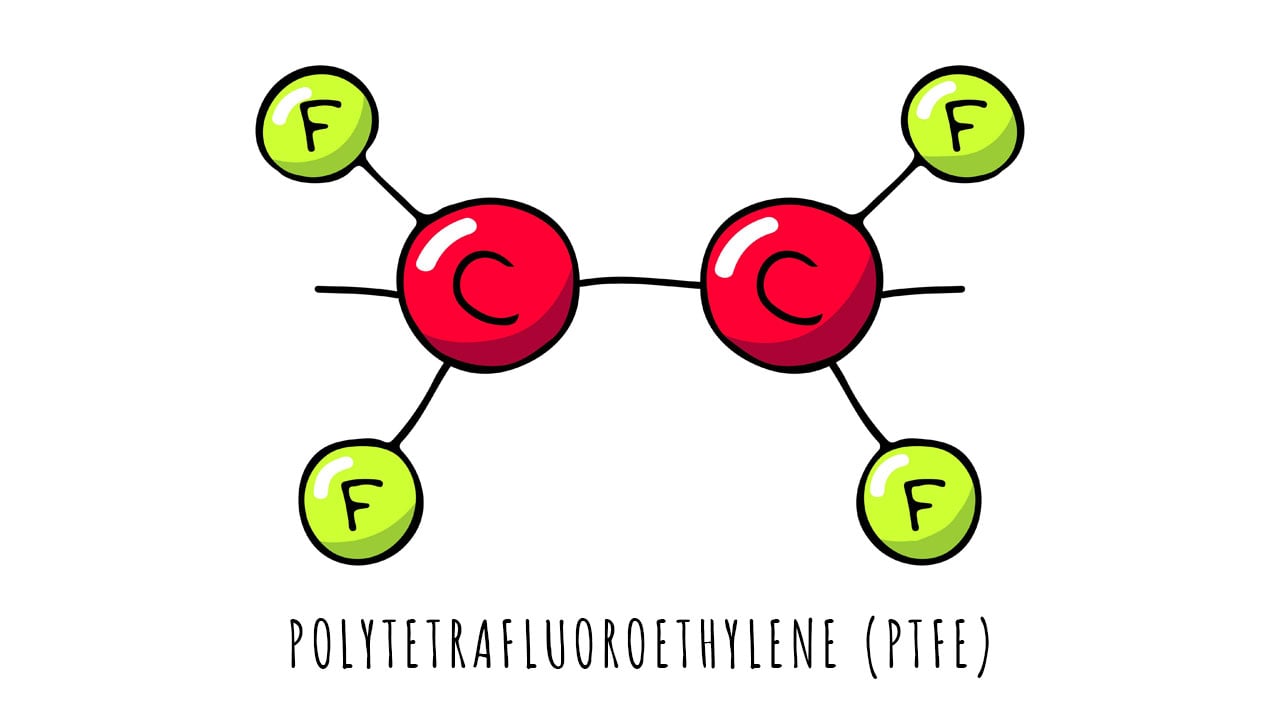

Fluoropolymers are a family of high-performance plastics characterized by their strong carbon-fluorine (C-F) bonds. This unique atomic structure...

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

To request compliance documentation click here.

2 min read

Fluoropolymers are a family of high-performance plastics characterized by their strong carbon-fluorine (C-F) bonds. This unique atomic structure...