1 min read

Thermal Expansion a Key Consideration in Plane Bearing Design

![]() Dave Biering

April 17, 2018

Dave Biering

April 17, 2018

We are all aware that plastics expand and contract at different rates. When designing plastic plane bearings, one of the most critical considerations is to understand the thermal reactions of the material; designing not just for the normal operating temperatures of your environment, but to consider the minimum and maximum operating temperatures as well. Otherwise, you may lose the press fit (in cold temperatures) or expand to the point of shaft seizure (with hot temperatures).

Here’s a Basic Definition for Thermal Expansion

“Thermal expansion is the tendency of matter to change in shape, area, and volume in response to changes in temperature.”

Expanding (pun intended) on that, the Wikipedia page for thermal expansion offers some solid information, like how expansion is a result of the change in kinetic energy of molecules. Also included is a table a comparison of various materials.

Calculating the Coefficient of Linear Thermal Expansion (CLTE)

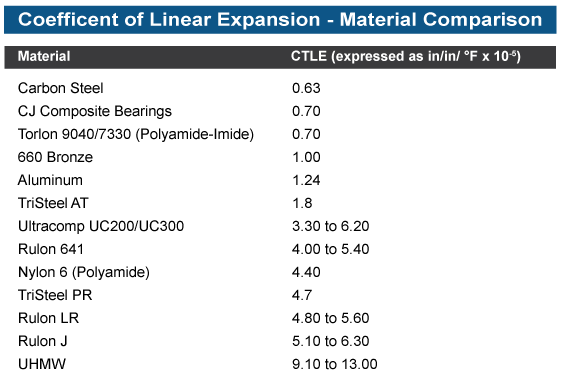

The Coefficient of Linear Thermal Expansion is a critical metric when working with dissimilar materials in applications where large temperature changes are anticipated.

This measurement is the ratio of the change in a linear dimension to the original dimensions of the material for a unit change of temperature. This is generally expressed as in/in/°F.

When it Comes to Thermal Expansion - Some Materials are Definitely Better Than Others

Our CJ material has a similar thermal expansion rate to steel, so we can run much tighter press fits and ID tolerances because the materials will stay stable from cryogenic to 350° F.

Some exotic materials like Torlon and polyimides also have good thermal expansion rates. On the other hand, UHMW would not be a good choice in an application with extreme heat as it has up to 13x the thermal expansion of steel!

Here is a breakdown of linear expansion in some of the key materials from our tier one product line along with some other common materials.

We can Help

This is a lot to unpack! We can answer any questions you might have about thermal expansion. Let us review your materials and design criteria.