1 min read

How do Self-lubricating Bearings Work to Eliminate Greasing?

![]() Adrian Carrera

January 23, 2026

Adrian Carrera

January 23, 2026

Industry research shows that up to 80% of all industrial bearing failures; catastrophic, functional, or premature; are related to improper lubrication. This staggering statistic highlights just how much downtime, maintenance cost, and equipment damage can be tied to grease and oil dependency.The challenges associated with manual greasing are well-documented:

- Poor lubricant selection for the environment

- Incorrect application leading to uneven coverage

- Lubricant contamination from dirt, dust, or fluids

- Degradation of grease over time under heat or load

Without proper lubrication, bearings cannot effectively distribute heat, resist corrosion, or minimize friction. The result? Premature bearing failure, unplanned stoppages, and higher total cost of ownership.

How Do Self-Lubricating Bearings Solve This Problem?

A common question we hear on Tristar’s Ask the Expert portal is:

“How do self-lubricating bearings actually work to eliminate the need for manual greasing?”

The answer lies in their inherent lubrication characteristics.

Built-In Lubrication Properties

Self-lubricating polymer bearings are engineered with solid lubricants distributed throughout the bearing material. This means the lubrication is integral to the bearing itself, not something that needs to be applied externally.

Expert Note from Tristar: Unlike metal bearings that rely on a thin film of grease or oil, polymer bearings maintain a consistent lubrication layer throughout their lifespan.

Why Greasing a Self-Lubricating Bearing Can Cause Damage

Manually applying grease to a self-lubricating bearing can actually do more harm than good. Grease becomes a lapping compound, trapping debris and grinding it into the bearing surface. Instead of reducing wear, this contamination accelerates it and shortens service life.

This is why Tristar engineers never recommend adding grease to polymer bearings. Their self-lubricating properties already optimize performance.

Benefits of Eliminating Grease with Tristar Bearings

- Reduced Maintenance & Downtime: No re-lubrication schedules mean fewer interruptions and lower labor

- Cleaner Operation: Ideal for food processing, medical devices, and cleanroom environments where contamination must be avoided.

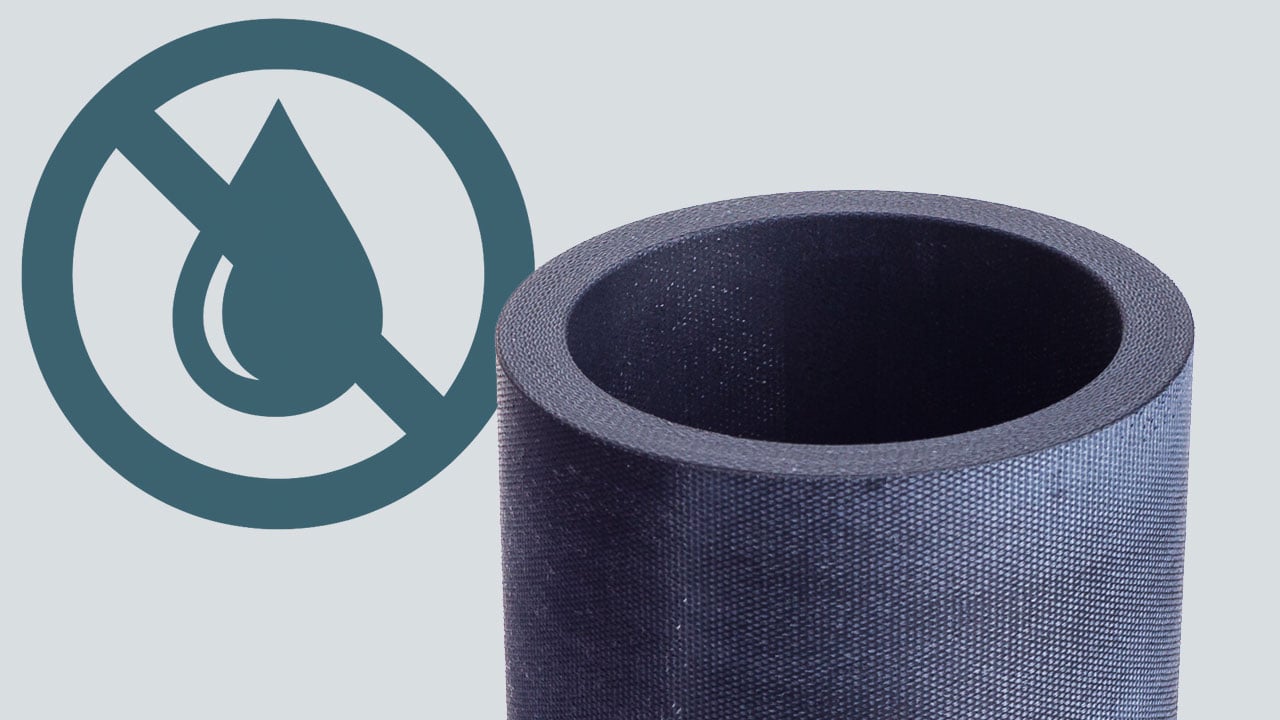

- Reliability in Harsh Environments: Dry-running design resists dirt, dust, and moisture that compromise metal bearings.

- Extended Bearing Life: Uniform self-lubrication reduces wear and prevents premature failures.

Video: See How It Works

Check out our short video below to see how self-lubricating bearing systems function and why industries worldwide trust Tristar for oil-free, maintenance-free solutions.

Why Engineers Trust Tristar Plastics

At Tristar, we’ve spent more than 40 years helping engineers replace greased metal bearings with smarter polymer alternatives. Our customer-first approach ensures:

- Expert Guidance: Material selection tailored to your application.

- Proven Solutions: Products like Rulon® and Ultracomp® designed for long-term reliability.

- Global Industry Trust: Bearings used in aerospace, food processing, agriculture, marine, and medical applications worldwide.