2 min read

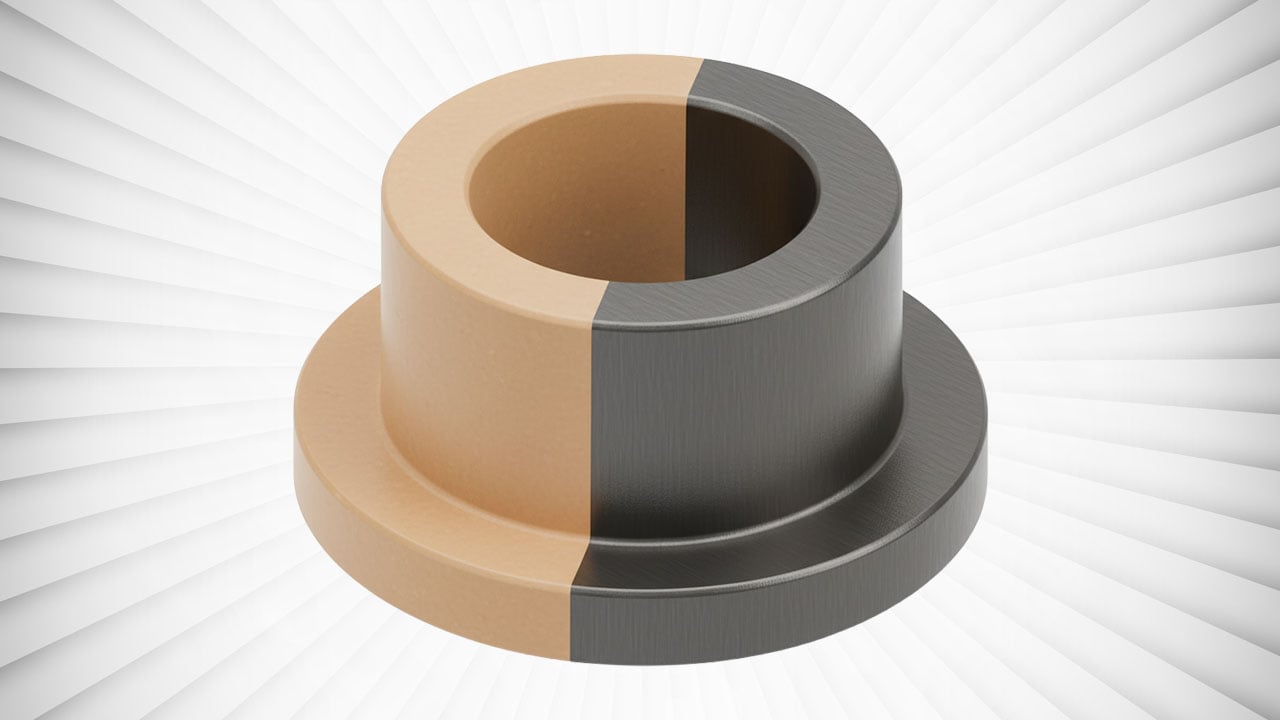

Q&A How Do Plastic Bearings Compare To Standard Metal Bearings?

![]() Adrian Carrera

January 14, 2026

Adrian Carrera

January 14, 2026

It’s a question that continues to be widely debated: how do plastic bearings compare to metal bearings?

In some industries, engineered plastics are regarded as premium bearing materials, while in others, the misconception persists that plastic is inferior to metal.

To clear the air, Tristar’s engineering experts compared plastic and metal bearings across three critical performance factors: maintenance, durability, and service life. Here’s what we discovered.

Maintenance: Plastic Bearings Deliver Grease-Free Performance

Lubrication is essential to any bearing’s performance, especially during initial equipment startup, when machines run “dry.” Without sufficient lubrication, friction, heat, and wear accelerate rapidly.

Plastic bearings have a major maintenance advantage

They feature built-in self-lubrication, meaning each bearing component continuously lubricates itself from day one. Because these materials inherently resist the effects of stick-slip motion, they deliver smoother operation and longer wear life; all without requiring manual greasing.

By contrast, metal bearings require frequent manual greasing to maintain proper lubrication. Each greasing interval means maintenance downtime, added labor, and higher operational costs.

In short:

- Plastic bearings: Maintenance-free and continuously lubricated

- Metal bearings: High-maintenance, grease-dependent

Expert Note from Tristar: Many engineers underestimate the cost of lubrication. In industrial applications, up to 30% of total bearing maintenance costs can be attributed to greasing schedules and contamination cleanup. Self-lubricating plastic bearings—like Tristar’s Rulon®, CJ, and Ultracomp® series—eliminate that cost entirely, providing a cleaner, longer-lasting, and more sustainable solution.

Durability: Plastic Bearings Handle Heat and Load Differently

A common myth in bearing design is that thin-walled plastic bearings are less durable than thick-walled metal bearings.

Nothing could be further from the truth.

Thin-walled plastic bearings actually dissipate heat more effectively than their thicker metal counterparts, which helps extend their lifespan. A thinner wall also allows for better clearance and lower friction between the shaft and bearing surface.

While metal bearings are often made thicker to compensate for surface wear, the additional material does not prevent failure, especially in high-friction or contaminated environments.

Ultimately, durability depends on material selection and operating conditions, not wall thickness. Learn how reinforced plastic bearings extend wear and reduce costs in high-speed rotary applications.

Service Life: Predictable, Proven, and Longer

Plastic bearings consistently deliver longer service life than oil-impregnated bronze bearings; and that’s not just anecdotal.

Their performance can be quantified through tribology testing, a science that measures friction, wear, and temperature under simulated application conditions. These data-driven tests allow Tristar engineers to predict the exact lifespan of a bearing before it’s deployed.

Tribology also ensures quality assurance, verifying that plastic bearings meet industry standards for chemical resistance, pressure velocity (PV) limits, and thermal performance.

Conventional metal bushings, on the other hand, are generally rated by base material standards and depend on external lubrication. As a result, their long-term wear behavior can vary significantly depending on application conditions.

Expert Note from Tristar: When we evaluate bearing life expectancy, we rely on decades of tribological data collected from thousands of test runs in simulated environments. This allows our engineers to tailor each bearing material—such as Rulon®, Ultracomp®, or TriSteel™—to its specific load, speed, and environmental requirements.

Industry Applications

Plastic and composite bearings are now standard in industries that demand low maintenance, corrosion resistance, and predictable wear performance, including:

- Food processing (FDA-compliant Rulon® grades)

- Medical and laboratory equipment

- Aerospace and defense systems

- Marine and underwater equipment

- Heavy equipment and construction machinery

- Semiconductor and cleanroom environments

Expert Note from Tristar: Today’s plastic bearings are not “cheap substitutes” for metal, they are engineered solutions optimized for performance. Whether your system requires chemical resistance, dry lubrication, or high PV ratings, Tristar can match your application to the right bearing material for maximum reliability and lifespan.

Ready to Compare Materials for Your Application?

- Ask our Experts about the right plastic bearing solution for your system.

- Explore our Rulon Materials Comparison Chart

- Learn more in our Bearings 101 Guide