1 min read

How it Works: Coordinate Measuring Machine for Plastic Fabrication

![]() Dave Biering

July 11, 2017

Dave Biering

July 11, 2017

We’ve got an exciting new addition to our plastic fabrication shop – a new coordinate measuring machine! Today I want to share some of the benefits of this new equipment, and explore how it can help you realize your product design dream.

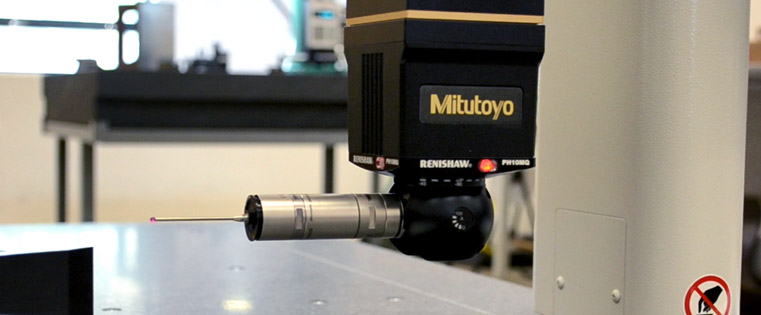

Our new Coordinate Measuring Machine is now a key feature of our testing and inspection lab. It measures the geometrical characteristics of a component, and shows the collected data in a mathematical form using X, Y, and Z axes. The measurements are obtained via a probe that is attached to the third moving axis of the machine. The CMM allows for incredible accuracy and precision to within a micrometer.

What is the importance of a CMM in plastic fabrication?

Essentially, our goal of acquiring this machine is to enhance our quality commitment. We look to the CMM to test if engineered parts are up to the rigorous specifications of an application design. And beyond accuracy and product integrity, the machine also helps to ensure that a manufacturing process is repeatable. This CMM model is designed for large assemblies and will help us to increase throughput.

The CMM machine is just one piece of our custom plastic fabrication machine shop, which boasts:

CNC Swiss Screw Machines

- High-speed turning

- Bar capacity up to 1.25”

- Continuous bar feeding

- 6-axis control system

- Secondary milling and drilling

CNC Milling

- Up to 36” x 81” travel

- Rapid tool change

- Close tolerance

- Prototype/production

- CAD/CAM

CNC Turning

- Live mill head attachments

- Bar capacity up to 2.75”

- Secondary milling & drilling

- Chucking capacity up to 21”

Consider TriStar’s plastic fabrication; we can guarantee your parts will meet design specs and that they are fully inspected and certified.

We can also help you save on component costs by suggesting alternate materials, or providing machining tips to help you manage your own fabrication. Get your copy of the Plastic Fabrication White Paper for exclusive machining tips! Let us help!