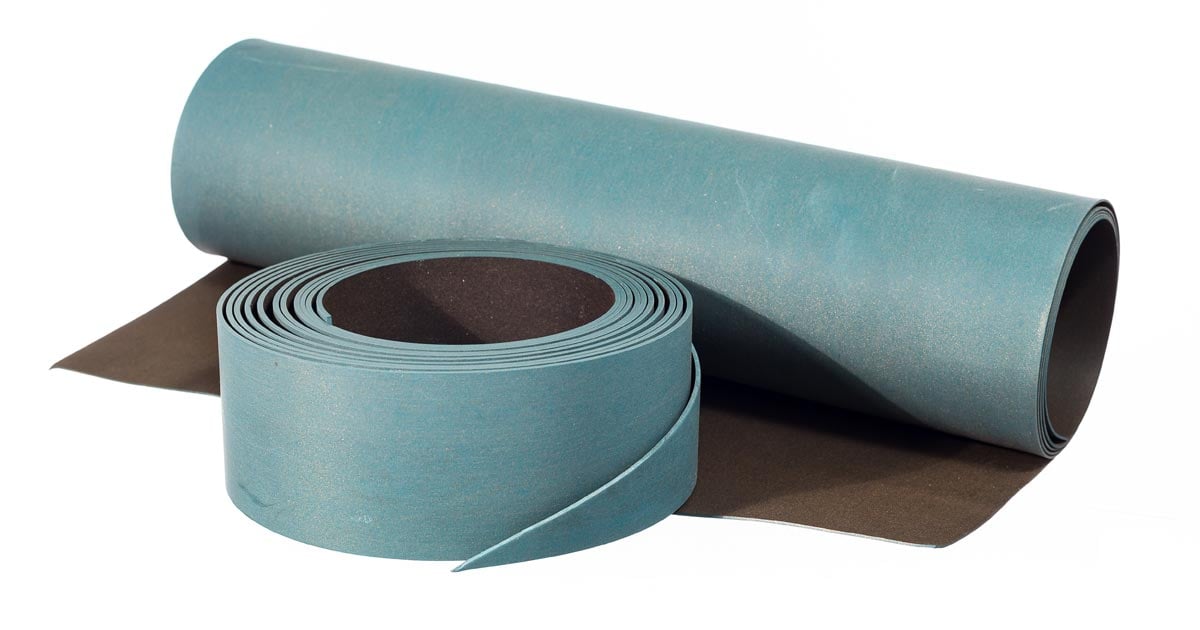

This was an excellent question from a customer wondering how long they could store non-etched Rulon materials.

Rulon and PTFE Shelf Life: Key Factors

When handled and stored properly, Rulon has an unlimited shelf life. But when the material is etched, the answer is not quite as simple.

When stored in normal warehouse conditions, all PTFE and Rulon materials have an unlimited shelf life. In fact, a common industry joke is that, at 85 years and counting, PTFE has “not been around long enough” to determine how long it will last!

But etched-PTFE and Rulon are a different story. The etching process involves reducing the surface lubricity of the polymer in order to bond it to another material. For best results, etched materials must be stored in a black, UV-blocking bag or else the etch will degrade at about six months. The UV bag also protects Rulon materials from damaging ozone and heat exposure, which is common to a warehouse environment. With this protection, etched materials can last a year.

Rulon/Ptfe Degradation: How Can I Tell If My Material Is Degrading?

To determine if your PTFE/Rulon material has degraded, we recommend two methods:

- Look at the color ― if it has faded to a light brown/tan or has a marbled look, it is no longer a viable manufacturing material.

- Try a droplet test – add a drop of water and if it rolls around in a ball the material is now hydrophobic and the etch has been lost. If it disperses, than the etch is still hydrophilic and the material is good to go!

Still not sure about the shelf-life of your stored Rulon materials? Need a second opinion? Just connect with the official Rulon experts!

Rulon and PTFE have key advantages over traditional materials in a broad array of applications like bearings. You can learn about these advantages (like self-lubrication and friction coefficients) on our Bearings 101 page.