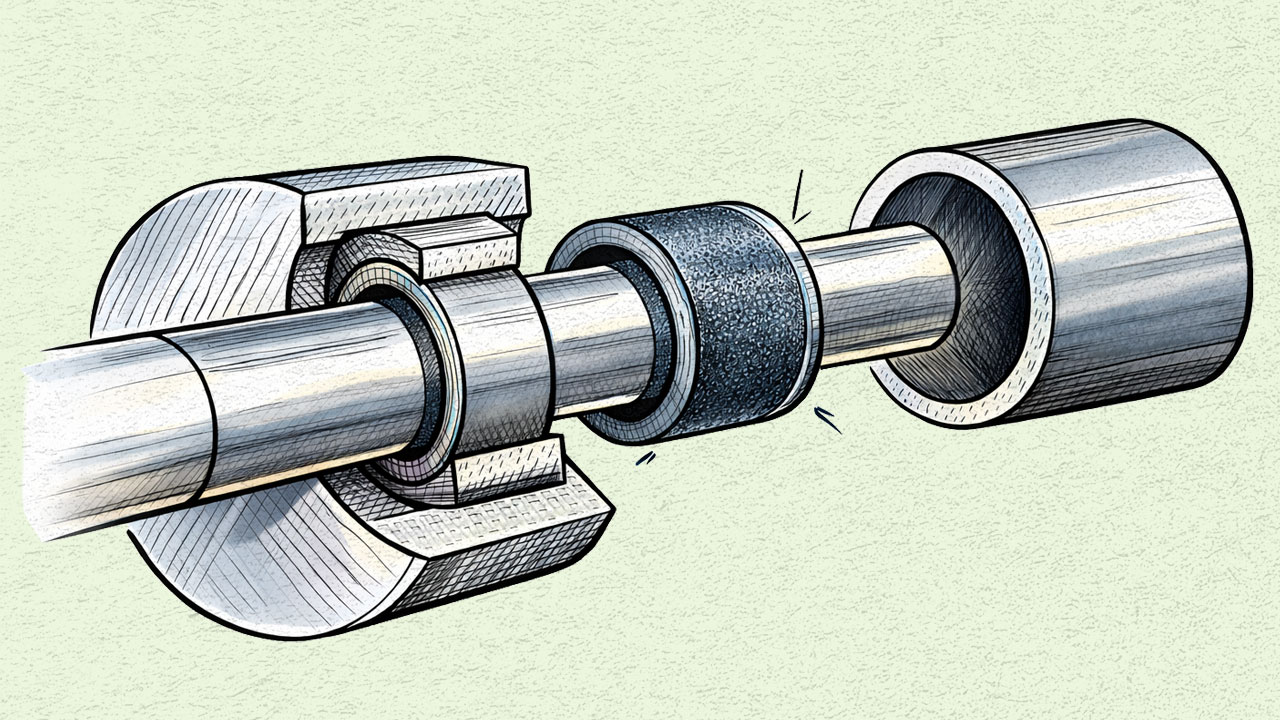

I had a great conversation this week about bearing selection and one of the most misunderstood but critical design variables: press fit. Press fit is defined as the intentional interference between mating components, typically:

- The shaft OD and bearing ID, or

- The bearing OD and housing bore ID

In plastic and composite bearings, press fit is not optional, it is a core engineering requirement. Getting it right ensures proper retention, torque transfer, and long-term service life. Getting it wrong can lead to premature wear, heat buildup, creep, or bearing migration.

Why Press Fit Matters in Bearing Selection

Press fit directly affects bearing performance, reliability, and lifespan.

Without a properly engineered press fit:

- Bearings can spin or walk in the housing

- Running clearances collapse due to thermal expansion

- Friction and heat increase dramatically

- Dust and abrasive particles infiltrate the interface

- Axial location and torque transfer are compromised

This is especially true for self-lubricating polymer and composite bearings, where material behavior differs significantly from metals.

Press Fit Engineering for Ultracomp® Composite Bearings

To generate a proper press fit for Ultracomp® filament-wound composite bearings, TriStar Plastics engineers require the following application data:

- Housing bore diameter and tolerances

- Shaft diameter and tolerances

- Operating temperature range (minimum and maximum)

- Motion type (rotary, oscillating, or linear)

- Load and vibration characteristics

Unlike metal bearings, composite materials respond elastically to interference and temperature changes. This makes press fit calculation an engineering exercise, not a rule-of-thumb decision.

Example: Press Fit Calculation (Ultracomp®)

The following example illustrates how TriStar evaluates press fit under real operating conditions:

The following example illustrates how TriStar evaluates press fit under real operating conditions:

- Housing bore: 0.5934″ – 0.5941″

- Shaft diameter: 0.498″ – 0.499″

- Temperature range: 68°F to 200°F

From this data, TriStar engineers calculate:

- Required interference

- Expected material compression (“close-in”)

- Running clearance at operating temperature

- Impact of thermal expansion and vibration over time

This ensures the bearing maintains proper clearance during operation without excessive friction or risk of migration.

Additional Factors That Influence Press Fit Performance

Material Creep

Plastic and composite bearings experience time-dependent deformation under load, known as creep.

If creep is not accounted for:

- Interference can relax over time

- Bearings may lose retention

- Alignment and clearance can shift

TriStar incorporates creep behavior into press fit calculations, especially for high-load or continuous-duty applications.

Vibration and Dynamic Loading

Rotational and oscillating systems generate vibration that can:

- Loosen poorly designed press fits

- Accelerate wear at contact surfaces

- Increase heat generation

A properly engineered press fit stabilizes the bearing under vibration, preserving axial position and load distribution.

Thermal Expansion

Temperature changes dramatically affect press fit in polymer bearings.

As temperatures rise:

- Bearing materials expand more than metals

- Interference increases

- Running clearance decreases

TriStar evaluates press fit at both ambient and peak operating temperatures to prevent seizure or excessive friction during operation.

Key Press Fit Considerations

- Interference fit: A fastening method achieved through friction, created when two parts are pressed together with intentional dimensional interference.

- Thermal expansion: The tendency of materials to change volume with temperature, directly affecting bearing clearance and fit.

- Running clearance: The operational free space between shaft and bearing ID (or bearing OD and housing) after installation and thermal effects are considered.

- Close-In (Ultracomp® Specific): The percentage of material compression resulting from press fit interference. Close-in depends on bearing wall thickness and shaft diameter, and improper calculation can lead to overheating or failure.

Expert Note from TriStar: Press fit design is one of the most common causes of premature bearing failure in polymer and composite applications. Our engineers don’t rely on generic tolerances; we calculate press fit based on material behavior, temperature range, creep, and vibration. That’s how Ultracomp® bearings achieve stable clearance and long service life in demanding environments.

Press Fit + Engineering Support = Reliable Bearing Performance

Achieving the right press fit is not just a dimensional exercise; it’s a system-level design decision. When properly engineered, press fit:

- Maintains bearing position under load and vibration

- Preserves running clearance across temperature swings

- Improves torque transfer and alignment

- Extends bearing service life

- Reduces maintenance and downtime

This is why TriStar treats press fit as part of bearing selection, not an afterthought.

Want help calculating the right press fit for your application?

- Fill out a Design Worksheet for a custom press fit and material evaluation

- Ask a TriStar Expert to review your bearing selection and installation requirements

For more on machining and tolerancing plastic bearings, explore our Machining Plastics White Paper.