Education Creates Strong Partnerships

For almost 40 years our focus on education and collaborative engineering has been the cornerstone of building strong partnerships with our clients. This month, we are highlighting some of the key educational resources we have created over the years.

The blocks below highlight some of our most popular educational assets and we encourage you to explore. Whether you prefer on-demand videos, long-form webpages, blog posts, or downloadable white papers, we think you’ll find something to interest you. Also included is our recently enhanced material database (450+ materials) which now includes a built-in bearing PV calculator.

White Papers

Downloadable guides to bearings, industries and plastic engineering topics

Case Studies

An Ever-Expanding Library of Real-World Application Stories

Tech Talk Blog

Our Bearing Blog (Explore, learn, engage)

Video Learning Center

Extensive library highlighting our tier-one products and bearing topics

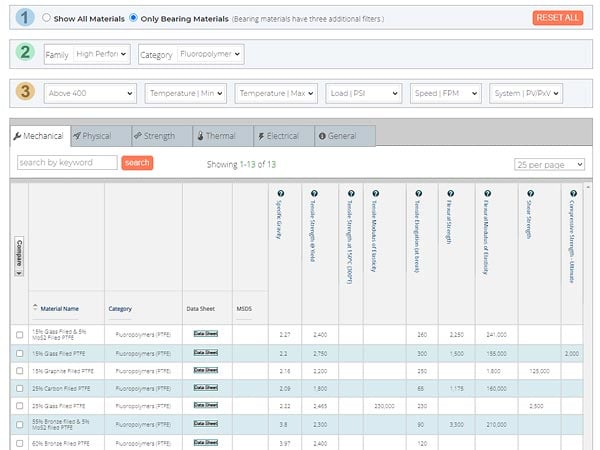

Material Database

Research and Compare plastic and composite materials (450+ materials)

Pillar Pages

Deep dives into materials and the industries that benefit from them

Technical Library

Tabbed Web Resource with Case Studies, Brochures, Newsletters, and Tech Docs

We hope you have found this useful and if you have any feedback on anything you see here or if you would like to discuss an engineering challenge with our team, we encourage you to reach out.