Specialized Membranes

Untreated/Treated for Filtration Applications

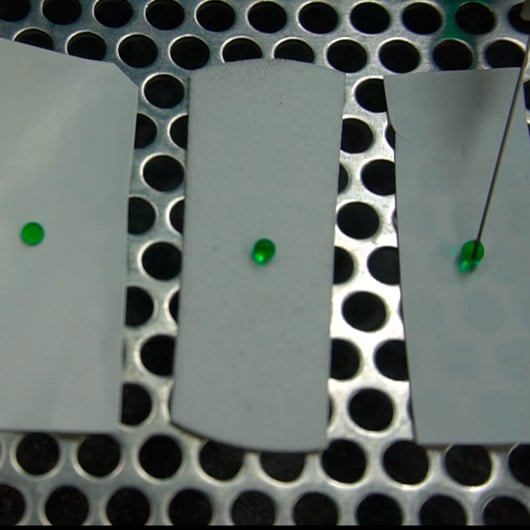

Membranes are thin sheets of semi-permeable material used to separate contaminants from water when a driving force is applied.

Membrane processes are increasingly used for removal of bacteria, particulates, microorganisms, and natural organic material.

Types of Membranes we Offer

We offer membranes with a variety of styles, pore sizes and applications. Some filter media polymers we sell are:

- PTFE

- PES

- PVDF

- Nylon

- PP

PES and PTFE Membranes

The most common membrane materials we offer are PES (polyether sulfone) and PTFE membranes. PTFE membranes are most often specified for water filtration applications like bottle filling, produce wash down, or other food industry processes.

Polysulfone allows easy manufacturing of membranes, with reproducible properties and controllable size of pores down to 40 nanometers. Such membranes are used in applications such as IVD (In Vitro Diagnostics), wastewater recovery, food and beverage processing, and gas separation.

These polymers are also used in the automotive and electronic industries. Filter cartridges made from PTFE membranes offer extremely high flow rates at very low differential pressures when compared with nylon or polypropylene media.