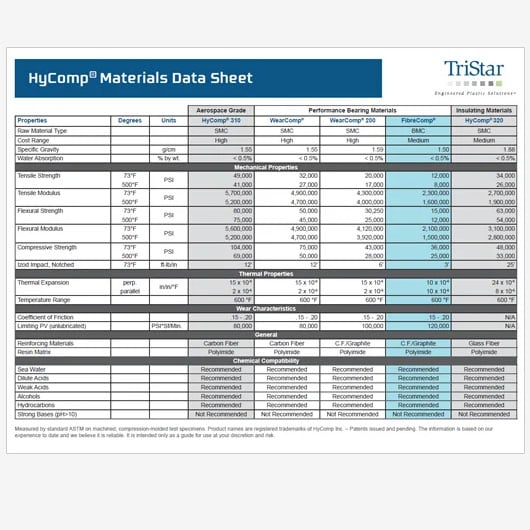

H310™

H310 is an aerospace-grade blend of high-temperature resin thermoset polymer sheet molding compound (SMC) with one-inch chopped carbon fiber reinforcement.

Applications vary from bushings, guide rings, wear liners, seals, clamps, and thermal isolators.