Enhanced Materials

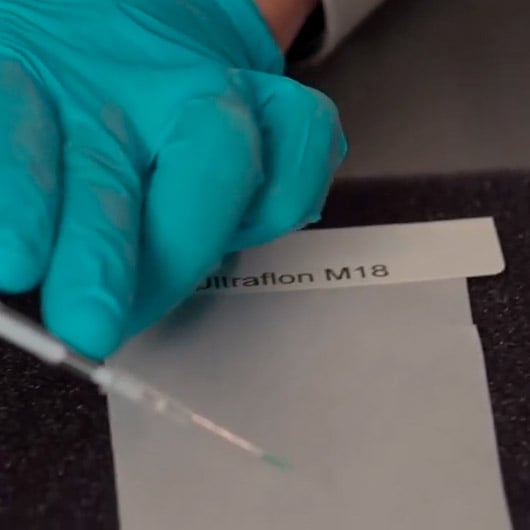

Plasma Treatment | Surface Modification | Membranes

Our Enhanced Materials Division (EMD) positions TriStar Plastics as the leading resource to solve your demanding engineering material challenges.

From cutting-edge enhancements that improve and extend the performance of polymers and elastomers to custom specialized membranes, we can help you find the best, most cost-effective way forward.

We offer...

- Plasma Treatments

- Surface Modification

- Specialized Membranes

- Customized Projects

We also offer close-tolerance cutting, customized stocking programs and J-I-T delivery.

Do you have a question for our polymer scientist?

Enhanced Materials Division

Learn about the advanced products and services available from EMD.