Rulon® LR | Superior Chemical Resistance

Among the most popular variations of Rulon, Rulon LR is the “Go-To” material for general purpose bearing applications.

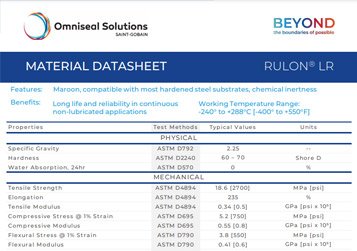

Rulon LR has a superior chemical inertness, with a ceramic filler for better dielectric and thermal insulation.

Our clients depend on Rulon LR’s durability and dependability for high-pressure gaskets, slide pads, compressor components, and light-to-medium duty structural applications. And sleeve bearings made of Rulon LR can operate up to 10,000 PV, or even higher with intermittent service.

Rulon LR gives the best chemical resistance for mild-to-hardened steel shafting and couterfaces.

|

Color |

Maroon |

|

Performance |

Max Load "P" (psi) Mpa: 1,000/6.9 |

|

Max Speed "V" (fpm) m/s: |

400/2.0 |

|

Max "PV" (psi-fpm) (Mpa × m/s): |

10,000/0.35 |

|

Mating Surface Steel and Stainless Steel |

Rc35 and higher |

|

Environment |

Steam, Wet, Dry, Vacuum |

|

Relative Rating (1=Low, 5=High) |

Coefficient of Friction: 4 |

|

Creep resistance: |

4 |

|

Insulative property: |

Yes |

|

Rod and Tube |

Extruded up to 10' long |

|

Sheet and Tape |

Tape 38" width max. Skived up to 1/4" thick |

|

Custom |

Contact us for custom shapes and sizes |

|

Automatic Molding |

Custom bearings |

|

Extrusion |

Rods and tubes |

|

Hand Molding |

Rod, sheet, and tube |

|

Machining |

Custom machined parts |

|

Skiving |

Tapes and thin sheet |

|

Stamping and forming |

Seals |