This study examined the relative adhesion difference between untreated polycarbonate (PC), mechanically roughened PC, and plasma treated PC. It appears that plasma surface modification of PC based polymers is a viable way to enhance adhesion prior to bond-up, lamination, or overmolding. This study observed approximately a 459% increase in lap shear bond strength after plasma treatment.

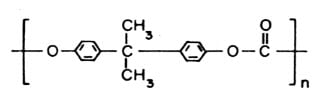

Polycarbonate is a specific group of thermoplastics. They are called polycarbonates because they are polymers having functional groups linked together by carbonate groups in a long molecular chain.

The most common type of polycarbonate plastic is one made from Bisphenol A, in which groups from Bisphenol A are linked together by carbonate groups in a polymer chain. This polymer is highly transparent to visible light and has better light transmission characteristics than many kinds of glass. Polycarbonate can be mechanically bonded by standard methods. It can also be cemented by using a solvent such as methylene chloride or adhesives such as epoxy, urethane and silicone. Polycarbonate and also be ultrasonically welded. Yet, solvent based adhesive can contaminate sensitive devices. Moreover, ultrasonic welding requires tight tolerances and smooth contaminate-free surfaces. The plasma treatment prior to bonding with common adhesive has shown an effective way to bond PC without solvent based adhesive or technically difficult, sonic welding.

A plasma is a quasineutral cloud of ion, electrons, and radicals. The diffuse cloud is capable of doing chemistry on the surface of materials that is unique, providing wettable or adherent surfaces on materials that are otherwise inert.

The PC samples in this study were subjected to a specific plasma gas mixture to induce and adherent surface for a structural epoxy adhesive. The results are as follows:

| Untreated PC | Mechanically Roughened PC |

Plasma Treated PC |

Plasma Treated PC Process 2 |

|

| Contact Angle | 98 degrees | 64 degrees | 22 degrees | 14 degrees |

| Pull Strength | 113.5 psi | 211.7 psi | 634.3 psi | 594.6 psi |

| Extension | 0.0264" | 0.0335" | 0.0779" | 0.0741" |

| Failure Mode | Adhesion (delamination) |

Adhesion (delamination) |

Adhesion (delamination) |

Adhesion (delamination) |

In summary, polycarbonate can be bonded using mechanical or solvent chemical methods. Yet, it has been proven that plasma surface modification is a viable, environmentally friendly, invisible treatment that can enhance the bonding performance significantly. If you would like more information about this process or other processes, please contact us at www.tstar.com.