Composite Bearings Power Energy Industry Innovation

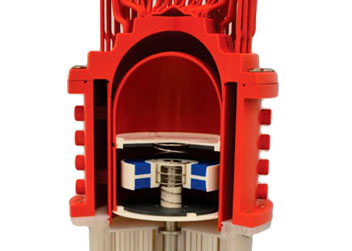

The oil and gas industry has high demands for polymer bearings.

Extreme temperatures and high loads, near-constant use, plus the increasing scrutiny of the industry’s impact on the environment are all top challenges.

TriStar’s polymer bearing materials have been specifically engineered for oil & gas applications. One such material is Rulon® 945. Boasting exceptional impact stability, plus heat and chemical resistance, 945 is an ideal fit for extreme applications such as fracking.

Some other energy applications for composite bearings include:

- Compressor piston rings, wear rings, tensional seals used in every facet of the industry (from reinjection to pipeline transportation)

- Engine shaft seals used in fracking equipment

- Slide pads used in pipelines

- Wear pads on the elastomeric casing guides used in oil and gas drilling

- Drop-in composite replacements for bronze bearings used on the drill spoolers in offshore drilling equipment.