Heavy-duty applications call for superior bearing strength, but how is bearing strength actually measured? In essence, bearing strength is the maximum stress load that the unit can “bear” or hold before the structure fails. But bearing strength can also be measured in terms of tensile, compression, and flexural strength, plus bearing hardness. We’ve got the definition you need to help in your finding the right bearing strength:

How strong is your bearing? Ultimately, it needs to be strong enough to exceed the everyday operating conditions of your environment. After all, bearings are meant to carry the stress and load of your application, but best practice is to measure bearing strength conservatively, so as not to exceed design limits.

Bearing strength is often measured by:

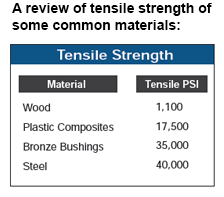

Tensile Strength

Tensile Strength

Tensile strength measures the ability of a material to withstand load under tension without failure. Also known as ultimate strength, tensile strength is measured in pounds per square inch (PSI). The higher the tensile strength, the stronger the bearing material, and the better ability it has to resist cracking.

Tensile Elongation

Tensile elongation is the increase in length that occurs when a material is stretched, but before it breaks under tension. It’s indicated as a percentage of the original length of the material. High-tensile strength and high-elongation are key factors in determining the overall toughness of a material.

Compressive Strength

Compressive strength refers to the resistance of a material to breaking under compression. Ultimate compressive strength is closely related to compressive strength.

Flexural Strength

Flexural strength is a material’s ability to resist bending under load (also known as modulus of rupture or bend strength).

Modulus

Modulus covers tensile, compressive and flexural strengths. It is defined as the ratio between the stress or force per unit area. The modulus of a material can predict the reaction of a material, as long as the stress is less than the yield of the material.

Hardness

Plastic hardness measures the ability of a material to resist indentation. See the Rulon bearing Selector Guide.

Beyond bearing strength, what other properties should you consider in your material selection? It’s also critical to review the bearing geometry, mating hardware, clean certification requirements (FDA, 3A), operating conditions, temperature variations and more. Get complete bearing selection help in the Plastic Bearing Design White Paper. Or for a custom consultation, submit a design worksheet.

We’re happy to help guide you to the right material!