Skip to the main content.

Let's Go Paperless

To save time and postage, please sign up for customer paperless invoicing, payments, and vendor payments.

Customers click here

Vendors click here

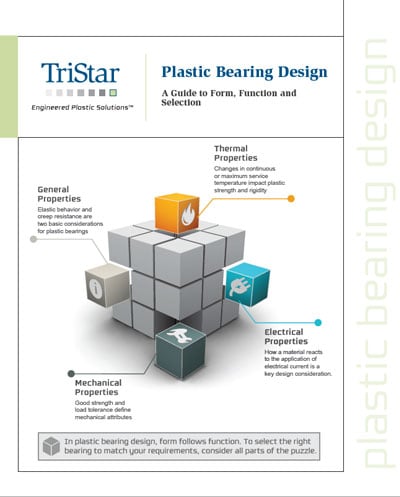

Plastic Bearing Design

A Guide to Form, Function and Selection

Between unique formulas, specialized liners and custom fabrication, there are thousands of plastic bearing design options available. But how do you identify the precise engineered plastic to fulfill your requirements?

Learn About:

- Plastic bearings vs. traditional metal bearings

- Comparison of relative bearing cost vs. performancee

- Bearing design considerations including key specifications